A Four-Wheel Success Story: How Volkswagen Transformed Bratislava

| Written by Mark Buzinkay

No video selected

Select a video type in the sidebar.

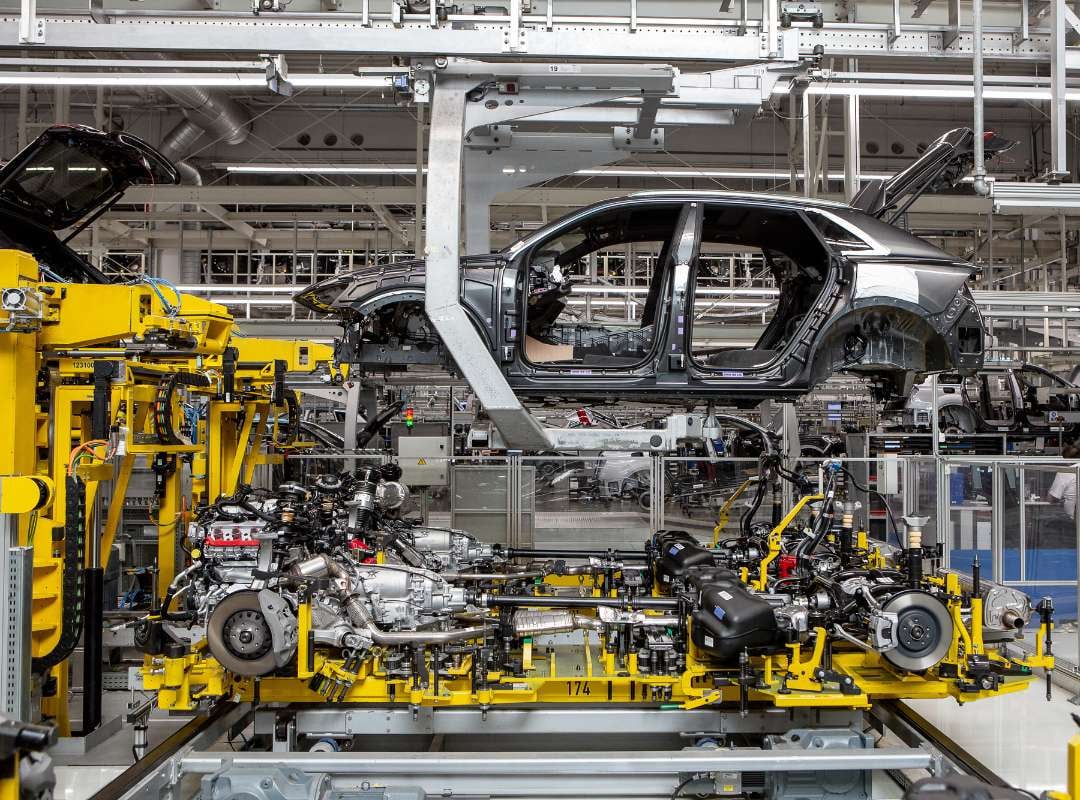

In the heart of Europe, a modern automotive fairy tale has unfolded. Bratislava, Slovakia's vibrant capital, has seen its industrial landscape renewed by the Volkswagen (VW) behemoth: First setting its roots in 1991, the VW plant has grown from a small dot into a veritable forest of innovation and production prowess.

Remember when the VW Touareg and Porsche Cayenne, the beloved models of the SUV world, were just fledglings on the automotive landscape?

Their transition into global icons began right here, in Bratislava, in 2002. In February 2010, birthing a new generation of these models, making the Touareg the most innovative vehicle since VW's inception.

The plant's story is a less conventional but equally compelling narrative in a city known for its fairy-tale castle and picturesque old town.

But Bratislava's significance doesn't stop at VW. It's an intricate gear in a global machine, producing cars for other major brands within the VW Group, like Audi, Porsche and Škoda. Bratislava's mastery of this mechanical ballet makes it a unique phenomenon on the global stage. Yet, it’s not just the city's economic backbone but also a source of pride, providing stable jobs for over 10,900 highly experienced and dedicated employees.

From birthing hybrids to fully electric cars, this plant has been a stalwart in VW's green initiative.

Its saga is far from over; it is a chronicle still being written in steel, aluminium, and electric sparks.

Matus: The Man That Makes The Flow Flow

When you walk through the sprawling campus of the Volkswagen (VW) plant in Bratislava amidst the cacophony of machines and flurry of activity, you'll find Matus Balog. A seasoned veteran with nearly a decade at VW, his journey is an inspirational tale of ambition, adaptation, and achievement.

Eight years ago, Matus, a fresh graduate from the Slovak University of Technology in Bratislava, stood at the threshold of the VW factory as one of the chosen few from over 2000 applicants to the VW trainee program.

Recalling his first day, Matus fondly reminisces, "I was full of expectations and amazed by the complex assembly process in the automotive business."

But it wasn't just about standing by and observing. Matus spent his initial days on the assembly line, immersing himself in the intricacies of the operation. These hands-on experiences provided him with a foundation that propelled his career forward, shaping him into a pivotal part of the VW team.

Over his tenure, Matus has seen the face of the automotive industry transform, primarily due to the dual impacts of COVID-19 and geopolitical tensions.

"We must be more flexible and more team-oriented," he says, "there is a need for adaptability in this ever-changing industry".

In response to these challenges, Matus, stationed at the Finish Centre department, spearheaded efforts to automate processes, increasing efficiency and resilience. A testament to his evolving role and responsibilities at VW.

His philosophy? "New day, new challenge." With an unyielding spirit, Matus embraces the brisk pace of change in the automotive world. Every system modification and every time constraint is an opportunity for him to flex his problem-solving powers and drive VW's mission forward.

No day without insights, learning and improvement

As the dawn breaks over the Volkswagen (VW) Bratislava plant, Matus gears up for another day filled with innovation and optimization at the heart of the automotive giant's production lines.

Stationed in the Finish centrum department, Matus is part of directing a symphony of IT production systems. His responsibilities are as multifaceted as the vehicles that roll off the assembly line. From ensuring the flawless operation of these intricate systems to spearheading innovative upgrades, Matus's role is pivotal in enabling workers to carry out their tasks efficiently.

A typical day for Matus is far from mundane. With each morning comes a fresh set of challenges and opportunities to improve and innovate. Like the cogs in the machines he tends to, Matus keeps the wheels of innovation turning, ensuring every system is updated and primed to facilitate the demanding work of the factory.

One such instance where Matus's ingenuity shone brightest was the successful implementation of the Automation of JIT (Just-In-Time) warehouse project. Tasked by his then-boss, Frantisek Kirnak, Matus and his team were challenged to streamline the ordering, storing, and steering processes of post-vehicle launch.

Answering the call, Matus engineered an ingenious solution. He developed a system that unified three disparate systems into a singular, streamlined powerhouse. Operating on a pre-defined logic, this system efficiently processes data and guides workers via interactive screens.

The fruits of Matus's labour were a monumental success, not only enhancing production efficiency but also leading to significant financial savings to the tune of hundreds of thousands of euros. A testament to his relentless pursuit of improvement and excellence.

Matus's commitment to continuous improvement and his triumphs in enhancing efficiency at the VW Bratislava plant illuminate the path for future innovators. His story, steeped in dedication and innovation, stands as an example of how individual contributions can drive collective success in the dynamic world of automotive production.

At VW Bratislava, the culture is built on the foundational principle of continuous improvement, a philosophy employees like Matus embrace. This concept underpins every production process, fostering a sense of responsibility among employees to consistently elevate their performance. From the factory floor to the managerial level, every individual is empowered to suggest improvements, no matter how minute. Guided by this ethos, novel solutions are discovered, trialled, and implemented across the plant. With a perpetual focus on honing efficiency, quality, and cost-effectiveness, this dynamic approach propels VW Bratislava further towards success.

Asset Agent, production efficiency and continuous improvement

Once a stranger to the production lines of Volkswagen Bratislava, Asset Agent is now an essential component of the factory's operations. It has been in use for more than 13 years now and became a trusted partner to run production processes smoothly.

As Matus explains, Asset Agent, underpinned by Real-time locating systems (RFID RTLS), has become instrumental in tracking every vehicle in the vast production facility.

The system's primary role is to provide an accurate location for each vehicle, which is especially critical in times of part shortages.

Asset Agent has evolved over the years, with a 3rd party application serving as the user interface in the past. Now, the team is working on a new Asset Agent user interface, signifying the constant adaptation and evolution inherent in Volkswagen's commitment to continuous improvement.

Matus's response is unequivocal when asked about Asset Agent's role in advancing this continuous improvement ethos: it upgrades efficiency by providing real-time information about parking lot occupancy and the location of any vehicle at a moment's notice. At the same time, it is crucial for identifying 'wastefulness of resources' (read more about Asset Agent in the main Volkswagen plant in Wolfsburg).

By integrating data from Asset Agent into new systems, as exemplified by the Automation of JIT warehouse project, they have constantly improved and streamlined their operations. This encapsulates Lean Management principles, continually finding ways to reduce waste, increase efficiency and maintain a system of constant improvement.

In the words of Matus, he can't imagine working without Asset Agent. It's a testament to how vital it has become in the quest for ongoing advancement, mirroring the broader commitment of Volkswagen Bratislava to be always moving forward and ever-improving, harnessing the potential of technology.

Automation and Artificial Intelligence

As our day with Matus comes to a close, we can't help but reflect on his infectious passion for innovation and his unwavering commitment to making automotive production better each day. What does the future hold in his eyes?

"Automation and artificial intelligence", Matus muses, looking out at the bustling Volkswagen plant floor. He sees the future where we make machines do what they do best - routine, repetitive tasks - freeing up humans to do what we do best - innovate, create, and solve complex problems.

In the midst of a global component shortage, Matus views the problem through a lens of opportunity. He observes the increasing need for the transposition of vehicles within the plant area and envisions a solution straight from the future - self-driving cars that move around the plant during post-assembly operations.

As we bid farewell to Matus, it's his hopeful vision of a self-optimizing, efficient future that lingers. The story of Matus at the Volkswagen factory in Bratislava is one of innovation and an unquenchable thirst for improvement. And his vision for the future? It's nothing short of bright. In the realm of continuous improvement, there's always another mountain to climb, and with people like Matus leading the way, the journey is just as exciting as the destination.

Dive deeper into one of our core topics: Real-time locating system

Glossary

Just-In-Time (JIT) is a production and inventory management strategy aimed at minimizing waste by producing goods only when needed. It reduces inventory costs, enhances efficiency, and improves workflow by aligning production schedules with demand. Originating in Japan, JIT emphasizes timely delivery of materials and lean manufacturing practices, making it widely used in industries like automotive and electronics. (2)

Sources:

(1) R. Tesoriero, J. A. Gallud, M. Lozano and V. M. R. Penichet, "Using active and passive RFID technology to support indoor location-aware systems," in IEEE Transactions on Consumer Electronics, vol. 54, no. 2, pp. 578-583, May 2008, doi: 10.1109/TCE.2008.4560133.

(2) Ohno, T. (1988). Toyota Production System: Beyond Large-Scale Production. Productivity Press.

Note: This article was updated on the 16th of January 2025

Author

Mark Buzinkay, Head of Marketing

Mark Buzinkay holds a PhD in Virtual Anthropology, a Master in Business Administration (Telecommunications Mgmt), a Master of Science in Information Management and a Master of Arts in History, Sociology and Philosophy. Mark spent most of his professional career developing and creating business ideas - from a marketing, organisational and process point of view. He is fascinated by the digital transformation of industries, especially manufacturing and logistics. Mark writes mainly about Industry 4.0, maritime logistics, process and change management, innovations onshore and offshore, and the digital transformation in general.