No Disruption: How automated reefer monitoring impacts safety and productivity simultaneously

| Written by Mark Buzinkay

Human errors occur: every human movement in a container yard is a potential incident. Consequently, automating services is not only a reasonable approach to maximize safety, but guarantees continuous crane operation.

This article aims to shed light on the safety challenges faced in container terminals and their profound impact on productivity and profitability.

No video selected

Select a video type in the sidebar.

Safety is paramount

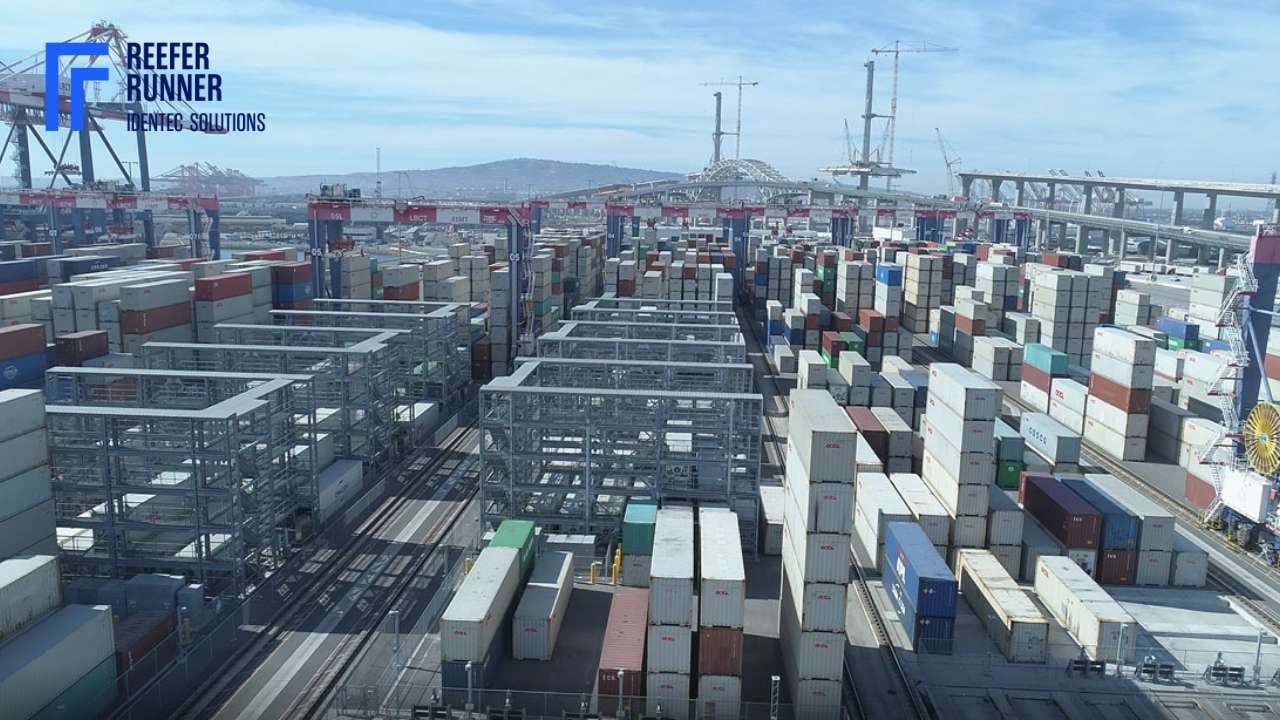

Container terminals serve as critical hubs for global trade, facilitating the movement of goods across vast distances. However, with the ever-increasing demands and complexities of the industry, ensuring safety within these terminals, particularly concerning reefers (refrigerated containers), is of paramount importance.

Container Terminals are hazardous places (1): Dockers may be dealing with a variety of vessels, people and weather under the pressure of a tight timetable. These ever-changing circumstances lead to ever-changing risks. In the UK, for example, incidents reported under RIDDOR increased by 16% in 2023, totaling 106 cases. (3)

By addressing personnel safety, accident prevention, harsh environmental conditions, fatigue management, and the potential of remote monitoring through automated reefer monitoring, terminal managers and directors can implement effective strategies to safeguard both their workforce and their bottom line.

Personnel Safety

Ensuring the safety of personnel working in container terminals is a top priority. Hazards such as heavy machinery, moving vehicles, and uneven surfaces pose significant risks. According to a study published in the Journal of Safety Research in 2019, titled "Risk Factors and Safety Measures for Terminal Operations in Container Terminals," implementing comprehensive safety training programs, promoting a safety culture, and utilizing advanced technologies like proximity sensors and warning systems significantly reduce accidents and injuries. The chart below illustrates the impact of safety measures on incident rates in container terminals.

Accident Avoidance

Accidents in container terminals can result in severe consequences, including injuries, damage to equipment and cargo, and disruptions to operations. To mitigate these risks, adopting proactive accident prevention measures is crucial. The implementation of automated systems, such as collision detection and alarm systems, as highlighted in a study conducted by the Transportation Research Board in 2021 titled "Enhancing Safety in Container Terminals Through Automation," has shown a significant reduction in accident rates. The chart below demonstrates the correlation between the adoption of automated accident prevention technologies and accident frequency.

Harsh Environment Conditions

Container terminals often face adverse weather conditions, including extreme temperatures, high winds, and heavy rainfall. These conditions not only jeopardize worker safety but also affect the integrity of reefers and the quality of perishable goods. The utilization of weather monitoring systems, as indicated in a report by the International Journal of Production Research in 2022, titled "Enhancing Safety and Efficiency in Container Terminals," enables terminal operators to anticipate and respond to harsh environmental conditions promptly. The chart below showcases the relationship between weather monitoring and reduced reefer malfunctions.

Fatigue Management

Fatigue among terminal workers poses a significant safety risk, as tired employees are more prone to errors and accidents. To address this challenge, the implementation of fatigue management strategies is crucial. Studies have shown that incorporating regular rest breaks, optimizing shift schedules, and utilizing fatigue monitoring technologies, as highlighted in a research article published in the Journal of Occupational and Environmental Medicine in 2020, titled "Fatigue Risk Management in Container Terminals," can effectively reduce fatigue-related incidents. The chart below depicts the impact of fatigue management strategies on incident rates.

Remote Monitoring of Assets and Processes

Embracing technological advancements, remote monitoring systems, specifically automated reefer monitoring, can revolutionize safety and efficiency in container terminals. By providing real-time data on reefer conditions, including temperature, humidity, and power supply, terminal managers can proactively identify and resolve issues remotely. A case study published in the Journal of Supply Chain Management in 2023, titled "Enhancing Safety and Productivity through Automated Reefer Monitoring in Container Terminals," showcases the benefits of remote monitoring in reducing equipment failures, improving reefer performance, and minimizing operational disruptions.

How can container terminals address safety challenges to improve productivity and profitability?

Safety challenges in container terminals, particularly regarding reefers, have a profound impact on productivity and profitability. By prioritizing personnel safety, implementing accident prevention measures, addressing harsh environmental conditions, managing fatigue, and embracing remote monitoring technologies such as automated reefer monitoring, terminal managers and directors can create a safer work environment, enhance operational efficiency, and safeguard their bottom line. By leveraging scientific research and industry best practices, container terminals can pave the way for a safer, more productive, and profitable future.

To do so, HSE departments create rules to avoid accidents. Not only to comply with legal regulations but also mitigate the chance of an accident, as learned from industry best practices. As the global container business grows year by year, the recruitment of low experience workers does as well. The expanding container business, a complex work environment, and inexperienced workers correlate with risk for occupational injuries, as shown by a study of the Port of Genova from 1980-2006 (2).

At the same time, operations in the yard must continue. A stop costs not only money but also impacts your reputation as a reliable service provider in terms of meeting your deadlines. Incidents and accidents will stop your operations and therefore, must be avoided. Training of staff in proper procedures are essential, but there remains the human factor that is responsible for most labour-related accidents in ports.

How Can safety And productivity Be improveD simultaneously?

One alternative approach is to automate specific process steps to minimize, or even exclude human intervention. Human errors occur: every human movement in a yard is a potential incident. Consequently, automating services is a reasonable approach to maximize safety and making reefer logistics much easier.

In the case of reefer management, most refrigerated containers are monitored manually. Crew members periodically read and check the temperature and power supply of every reefer in the terminal. This task involves a lot of movement in the yard, which is not only tiresome but interrupts operations as well. Yard cranes must stop when manual reefer monitoring is underway. These cranes cannot serve an entire rack or block for the duration of the inspection. To record the temperature of every reefer takes some time and the yard cranes become a bottleneck that impacts productivity. Finally, a container terminal risks missing deadlines.

Remote reefer monitoring avoids this. All reefer monitoring work is performed automatically, and all data is transferred to a central server. Instead of walking between reefers, operations managers and dockers can access real-time data on desktop or mobile devices. Container handling is not disrupted, and all processes can continue as planned, providing reliable services to customers and meeting operation timetables.

FAQ

What does RIDDOR mean?

RIDDOR (Reporting of Injuries, Diseases, and Dangerous Occurrences Regulations) is a UK regulation that requires employers, the self-employed, and responsible parties to report workplace accidents. Work-related fatalities, serious injuries, occupational diseases, and dangerous incidents must be given account. It ensures accountability and assists authorities in monitoring workplace safety trends to prevent future incidents. Reports are also submitted to the Health and Safety Executive (HSE) and contribute to compliance with existing and the development of new health and safety regulations. (4)

Takeaway

Terminal managers and directors should consider integrating automated reefer monitoring systems into their operations to stay ahead of the curve and maximise safety and efficiency. By harnessing the power of real-time data and remote control, container terminals can minimize risks, optimize resource utilization, and unlock new possibilities for growth in the rapidly evolving maritime industry.

Glossary

Dockers refer to dock workers responsible for loading, unloading, and handling cargo. They play a critical role in terminal operations, ensuring the efficient movement of containers between ships, trucks, and storage areas. Their work involves operating cranes, forklifts, and other equipment while adhering to safety protocols. Skilled dockers are essential for maintaining productivity and minimizing delays in port logistics. (5)

Perishable goods are items with a limited shelf life that can spoil, decay, or lose quality due to environmental factors like temperature, humidity, and time. These include food (e.g., fruits, vegetables, dairy), pharmaceuticals (e.g., vaccines), and flowers. Proper handling, storage, and transportation in controlled environments, such as cold chains, are essential to maintain their quality and safety. Effective management minimizes waste and ensures timely delivery. (6)

References:

(1) A quick guide to health and safety in ports (pdf)

(2) Port safety and the container revolution

(3) https://www.portskillsandsafety.co.uk/wp-content/uploads/2024/07/Port-Industry-HS-Benchmarking-Statistics-for-2023.pdf

(4)Stranks, J. (2016): Health and Safety at Work: An Essential Guide for Managers. Kogan Page.

(5) Branch, A.E. (2014): Elements of Shipping. Routledge.

(6) Kovač, U. (2010): Perishable Goods Supply Chain Management - Cold Chain Logistics. U. Kovač.

Note: This article was updated on the 9th of April 2025

Author

Mark Buzinkay, Head of Marketing

Mark Buzinkay holds a PhD in Virtual Anthropology, a Master in Business Administration (Telecommunications Mgmt), a Master of Science in Information Management and a Master of Arts in History, Sociology and Philosophy. Mark spent most of his professional career developing and creating business ideas - from a marketing, organisational and process point of view. He is fascinated by the digital transformation of industries, especially manufacturing and logistics. Mark writes mainly about Industry 4.0, maritime logistics, process and change management, innovations onshore and offshore, and the digital transformation in general.