Port Hamburg, Germany - Showcase of a Successful Strategy

| Written by Mark Buzinkay

No video selected

Select a video type in the sidebar.

What Makes the Port of Hamburg So Unique?

Overlooking the skyline of reddish buildings, moving ships and gulls screaming, it could be a port like any other in the northern hemisphere. But it is not; the port of Hamburg is different, not just because of the Elbphilharmonie: A myriad of water arms, brown and moving, 80km inland from the North Sea shore and still influenced by the tide. The port authority regulates the traffic on the river Elbe and designates which vessel enters the port, which ones have to wait and who has the next slot. Like a giant airport for container ships, cruisers, barges and everything else that floats, it must be regulated for the benefit of everyone.

The port of Hamburg is one of the biggest in the world, historically grown, constantly enhanced, changed, and improved. In 2023, the Port of Hamburg handled 7.7 million TEU (Twenty-foot Equivalent Units) and 114.3 million tons of cargo, solidifying its position as a leading global port. (3) Because of the sheer number of terminals, maybe it's more precise to say "the ports of Hamburg". Industrialisation during the 19th century enabled a massive increase in trading goods and pushed the need for bigger vessels and better port infrastructure. Ships became liners with somehow reliable schedules. Eventually, transhipment of goods started in Hamburg's Sandtorhafen in 1866: Warehouses stored cargo temporarily, and in 1872, direct unloading on rail began. Hamburg became the biggest rail port in Europe, constantly increasing the area and infrastructure of the port.

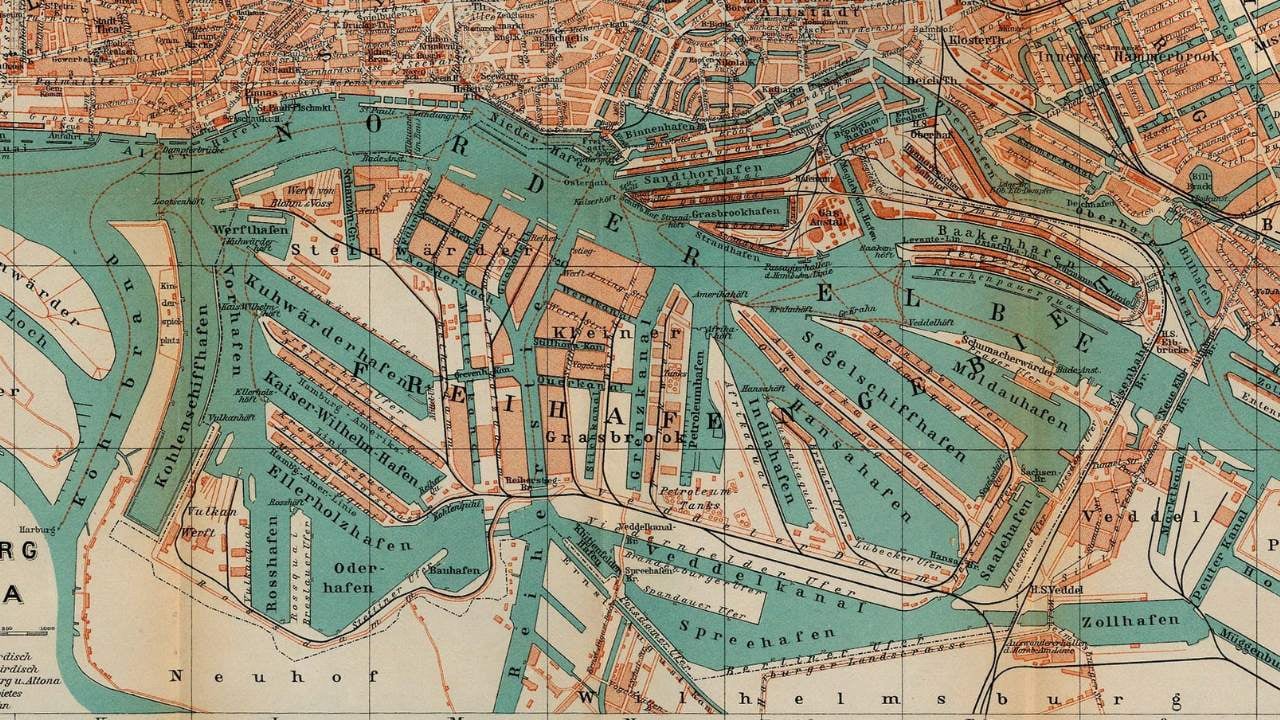

There are several terminals in Hamburg in this area, west of the Speicherstadt, located between Finkenwerder, Altenwerder, Grasbrook and Veddel. An old map of Hamburg Port marks it as "Freihafengebiet"; this terminal is home to many overseas terminals, all of them with their special character, charm and long history.

Some shipping companies originate from Hamburg, some from neighbouring countries like the Netherlands, and some with a history of roughly 200 years. Back then, such a shipping company was a family business and acted mostly as a shipping agent. Today, they are either part of a global player or developed as an independent global service provider by themselves, providing mostly storage, handling, forwarding, chartering and other commodity-related logistics services. Such companies employ today several thousand people across more many countries on all continents.

Typically, their long history is a continuing record of geographical expansion, technological adaptation and corporate understanding of markets. In short: A continued track of making customer needs possible. Over such an extended period, this is something extraordinary and tough to achieve. Just think about it in terms of historical changes: In the mid-1850, industrialisation went into full swing in northern Europe, Europe's dominance first expanded and then collapsed over two world wars, containerisation and globalisation of trade arrived, and digitalisation changed the face of our civilisation forever. The maritime companies you see today in Hamburg not only survived these periods of political shifts, economic challenges and technological revolutions but prospered to become a global player. "Asking me about the success formula of our company, I would say: best possible flexibility", says the Manager Processes and Technical Operations at one of those Hamburg terminals, "flexibility in every sense."

Flexibility. First of all, it is your location. For most shipping companies, this meant following the customer wherever they were, and eventually, it translated into dozens offices. Flexibility is also about your offering. Be prepared for whatever your customer may need and deliver on time. Some excelled in being open for all customer needs, servicing bulk, container, dangerous goods and sensitive cargo, and offering storage, handling and other logistics-related services. Some did not and perished.

Walking through one of the many Hamburg terminals, you still feel the old charm of mixed terminals – containers and bulk, almost everything is done manually. Cranes and container handling equipment need drivers, and you have an entire team administrating space and storage. You'll have to close off a public road to reach a separate warehouse and wait for the food truck to serve the dockers at 11:00 am every day. It doesn't matter in which direction you look; you'll always spot something different – bundles of copper plates, empty containers, big parts of wind turbines, mountains of aluminium and staples of cellulose, cables and powered reefers. It’s endless, it’s colourful.

"Our terminal is constantly changing", says the Director of Operations of another terminal in the area, "we adapt to our customer needs to stay flexible in a niche market. We'll find a solution if you need something extraordinary – sizes, types, or amounts." Being a well-known specialist, they need to be and evolve continuously as a specialist in flexibility.

How Do Hamburg's Terminals Stay Ahead in a Changing World?

In an ever-changing world, adaptation is a recipe for success, if not survival. As we can't control our environment, let alone shape it, we must make the best out of it. For niche terminals, it is not different. "Years ago, one of our customers asked for managing temperature-sensitive goods. Funny as it was, a weekly service left Hamburg to follow German Cruise ships and supply them with fresh food from home", says the vessel planner of a terminal further down the River Elbe. "Suppliers would deliver reefers to our terminal, and we would monitor them and provide power before they left for their own cruise."

From the first reefer at their terminal in Hamburg, Reefer Runner took over the routine work of monitoring refrigerated containers, sending alarms in case something went off course and delivering automated documentation of their stay in the yard. As a result, roughly one hundred reefer points are available at this particular terminal these days (look for other Reefer Runner stories with Yilport and Walvis Bay).

"Once we installed Reefer Runner, we never looked back. It saved us a ton of work", he says, "as we don't use racks for our reefers, we didn't want colleagues to climb reefers for a manual inspection in every weather, season and daytime." The remote monitoring functionality makes it obsolete and provides real-time data and alarms to the people in charge. The slowly increasing global demand for refrigerated containers is visible at this Hamburg terminal – new plugs will be ordered to cope with peaks.

The tiny investment in extra plugs is already paid off: within five years of Reefer Runner being installed at the terminal, there was only one claim. "And we rejected it successfully", mentions the Reefer Manager, "the automated recording by Reefer Runner delivered the proof that the cargo remained within the recommended temperature zone when we took care of it."

And there is another mega-trend in Europe the terminals in Hamburg have to find a way to manage it: The shortage of skilled labour. The demographic development in western countries creates a labour gap in all economic and public occupation sectors. Finding dockers and shipping terminals to optimise their processes is challenging to reduce the workload for the existing crews. Remote monitoring of reefers aligns with this strategy: You can keep offering a service to customers still with a fraction of the workforce. Remaining flexible is vital to everyone here around the River Elbe, offering a broad portfolio of services despite limited labour resources.

Did we mention external factors dictating the environment in which you must perform? Demography may be one; supply chain disruptions, pandemics, and war-related economic sanctions maybe some others. You'll find answers, and all terminal managers we talked to want to look deep into digitalisation. "Of course, we already harness digital technology of all kinds”, says one of them, “we investigate processes, uncover bottlenecks, and find solutions. Sometimes it is unspectacular like purchasing extra yard to combine surfaces; sometimes you'll have to think how to enable the energy transition in your terminal." For example, a green port requires a lot of electricity when substituting diesel-driven equipment and cranes, but you can't recharge all vehicles if there are no adequate power lines installed.

The green transition also changes the cargo managed in larger quantities: Lithium. Lithium is one of the main ingredients for electrifying traffic and liberating other sectors from fossil fuels. But at the same time, it is classified as dangerous goods due to their flammability. Therefore, some terminals will soon erect more extensive, dedicated areas for safe storage of hazardous shipments. Times change, but the long-valid success formula for Hamburg terminals, adaptation and flexibility, remains.

Have a deeper look into our collection of articles and papers around the world of refrigerated containers!

Glossary

Hamburg's Speicherstadt, the world's largest warehouse district, spans 260,000 square meters in the HafenCity quarter. Built between 1883 and 1927 on oak timber foundations, it served as a free economic zone for goods transfer without customs duties. Its Neo-Gothic red-brick architecture, canals, and bridges highlight maritime industrial heritage. Designated a UNESCO World Heritage Site in 2015, Speicherstadt remains a symbol of Hamburg's trade history, storing valuable goods like coffee, tea, spices, and carpets. (4)

Lithium is a chemical element with the symbol Li and atomic number 3, classified as an alkali metal. It is the lightest solid element, silvery-white in appearance, and highly reactive. Lithium has a density of 0.534 g/cm³, making it one of the few metals that can float on water. It readily reacts with air and water, forming lithium oxide or hydroxide. Its applications range from batteries to pharmaceuticals and alloys due to its electrochemical properties. (5)

References:

(1) https://www.hafen-hamburg.de/en/portofhamburg/geschichte/

(2) https://www.ihk.de/hamburg/en/produktmarken/economic/port-hamburg-fact-figures-1147536

(3) https://www.porttechnology.org/news/port-of-hamburg-ends-2023-at-8-million-teu/

(4) Hamburg's Speicherstadt: History. Architecture. World Heritage. Dölling and Galitz Publishing.

(5) Emsley, J. (2011): Nature's Building Blocks: An A-Z Guide to the Elements. Oxford University Press.

Note: This article was updated on the 9th of April 2025

Author

Mark Buzinkay, Head of Marketing

Mark Buzinkay holds a PhD in Virtual Anthropology, a Master in Business Administration (Telecommunications Mgmt), a Master of Science in Information Management and a Master of Arts in History, Sociology and Philosophy. Mark spent most of his professional career developing and creating business ideas - from a marketing, organisational and process point of view. He is fascinated by the digital transformation of industries, especially manufacturing and logistics. Mark writes mainly about Industry 4.0, maritime logistics, process and change management, innovations onshore and offshore, and the digital transformation in general.