Rig safety: How to improve your emergency response

| Written by Mark Buzinkay

The offshore industry is a remarkable example of technological achievements. However, offshore installations, FPSOs and other types of rigs are operating in the harshest environments, sometimes at great depths and under constant constraints of resources. The potential profits of offshore drilling are significant, but so are the risks. The factors mentioned above create a complex environment of hazards waiting to strike.

Therefore, safety must be the number one priority on these installations. Lives and wealth are at risk and must be secured because you care for the well-being of your personnel, and you are responsible for smooth and efficient operation in a risky environment at the same time. Therefore, one crucial approach to improving your emergency response is preparedness.

No video selected

Select a video type in the sidebar.

Table of contents:

- What Is Emergency Response?

- Rig Safety, Emergency Response And Preparedness

- What Categories Of Offshore Emergencies Exist?

- Environmental Emergency And Response Example: Oil Spill

- Offshore Safety Emergency Response Example: Evacuation

- Rig Safety: Offshore Evacuation Assessment

- FAQs

- Takeaway

- Glossary

WHAT IS EMERGENCY RESPONSE?

According to Safeopedia, emergency response "includes any systematic response to an unexpected or dangerous occurrence." HSE supervisors and managers design emergency response procedures to mitigate the impact of an event on people and the environment.

In general, emergencies warranting a response can range from natural disasters to hazardous materials problems and transportation incidents. Therefore, emergency response plans are prepared for specific scenarios and are critical to workplace safety.

A crucial aspect of emergency response is response time. Response time refers to how long it takes emergency responders to arrive at the scene of an emergency after the emergency response system has been activated. An extended response time can result in increased and permanent damage, a higher likelihood of fatalities, and greater distress to those involved. As such, response time is often used as a proxy for the effectiveness of an emergency response program.

Rig Safety, EMERGENCY RESPONSE AND PREPAREDNESS

Emergency response is an integral part of workplace safety for offshore drilling and all industries. The standards and awareness of occupational safety may differ from industry to industry because of historical reasons, the maturity of the sector and the type of potential hazards. But industries with the best safety procedures and emergency response plans had their wake-up call in their history regarding safety and human errors. Tragedies helped create awareness and the need to formulate and create strong regulations, methodology and safety culture. For offshore drilling, disasters such as Piper Alpha in 1988 initiated the development of well-organised EER procedures behind a strong safety awareness.

EER stands for evacuation, escape, and rescue and is the procedure in which people are taken to a safe ground during an accident such as a fire or explosion. The importance of EER is more critical in offshore drilling sites due to the surrounding water that poses additional safety risks.

For example, the Occupational Safety and Health Act (OSHA) requires employers to comply with hazard-specific safety and health norms. In addition, employers must provide their employees with a workplace free from recognised hazards likely to cause death or serious physical harm. Emergency Preparedness Guides do not and cannot enlarge or diminish an employer's obligations under the OSH Act, but are designed for use as a general handout during an emergency.

Such Emergency Preparedness Guides are based on currently available information and current occupational safety and health requirements and standards. The procedures and practices discussed in Emergency Preparedness Guides may need to be adjusted when additional, relevant information becomes known. As you want to comprehend and know the guidelines before an emergency happens, emergency preparedness guides are helpful training supplements for emergency preparation courses.

OSHA offers several emergency preparedness guides on their webpage

What categories of OFFSHORE EMERGENCIES exist?

As you can imagine, there are myriad offshore hazards. Most of them can be categorised into exposure to a wide range of hazardous substances, radiations, noise, vibration, extremes of heat and cold and ergonomic hazards. All have the potential to harm the health of workers, immediately or in later life.

HSE UK names five main groups of health hazards in the offshore oil and gas industry:

- Musculoskeletal disorders (manual handling, ergonomics)

- Hazardous substances

- Physical hazards (noise, vibration, asbestos and radiation)

- Biological hazards (food/water hygiene)

- Psychosocial hazards (stress)

HSE UK recommends a systematic approach to managing these health risks by applying a four-stage risk assessment for each occupational health risk. The risk assessment is a small but critical part of your overall management system (Planning and Setting Standards). The four stages of the risk assessment process are

- Identifying the health hazards

- Assessing the health risks

- Controlling the risks to health

- Mitigating the risks to health

The same approach is recommended to deal with potential emergency scenarios (e.g. emergency mustering). We will discuss two examples of emergency responses for rig safety: one case of an environmental emergency and one example of an evacuation and rescue emergency.

Continue reading about offshore safety standards here...

ENVIRONMENTAL EMERGENCY AND RESPONSE EXAMPLE: OIL SPILL

An oil spill can cause massive harm to the life and environment of open waters and coastal areas. There are many examples of catastrophic oil spills in the past, namely the notorious Exxon Valdez disaster in Alaskan waters and the oil spill caused by the Deepwater Horizon explosion in the Gulf of Mexico.

The (US) National Contingency Plan defines an oil discharge (spill) as "any spilling, leaking, pumping, pouring, emitting, emptying, or dumping of oil...". Because of the nature of oil, preparation plays a vital role in ensuring that employers and workers have the necessary equipment, know where to go, and know how to stay safe and healthy in the event of an actual emergency.

Preparing includes an oil spill response that typically identifies the number of workers required to mobilise and operate the oil spill response equipment at each site. In addition, all workers must have the qualifications and training necessary for their position within the response organisation. An oil spill response plan includes worker safety and health provisions for emergency response, recovery, and cleanup.

The employer's plan also includes the hazardous waste operations and emergency response (OSHA) in the aftermath of an oil spill. In addition, it must implement comprehensive safety and health programs that include components such as organisational structure, a comprehensive work plan, a medical surveillance program, standard operating procedures and PPE if needed, among other aspects.

For a complete introduction to how to prepare for and handle an oil spill, check the following link.

OFFSHORE SAFETY EMERGENCY RESPONSE EXAMPLE: EVACUATION

Evacuating 250 personnel from a platform is a complex procedure that requires prior extensive personnel training (see also: Persons on board). Think of the complex layout of the installation and the availability of escape routes and vessels. Proper emergency drills are critical contributors to the success of EER.

Successful rig safety will involve many parties, detailed procedures, and a variety of equipment that prevent fatalities during accidents on offshore drilling rigs. National regulations and industry-wide recognised best practices create standards for EER. They often include

- A detailed risk assessment

- A designated Emergency Control Centre (ECC)

- A well-practised, clear and functional Emergency Response Plan (ERP)

- An appropriate arrangement to raise an alarm

- The availability of communication equipment for personnel, vessels, emergency services and other support teams on and off the platform

- Ready-to-launch means for the immediate evacuation and rescue of people

- Designated muster areas and alternative muster areas

- 24/7 up-to-date list of all personnel

Just don't forget: An EER should be practised and practised, including all offshore safety equipment.

Rig Safety: OFFSHORE EVACUATION ASSESSMENT

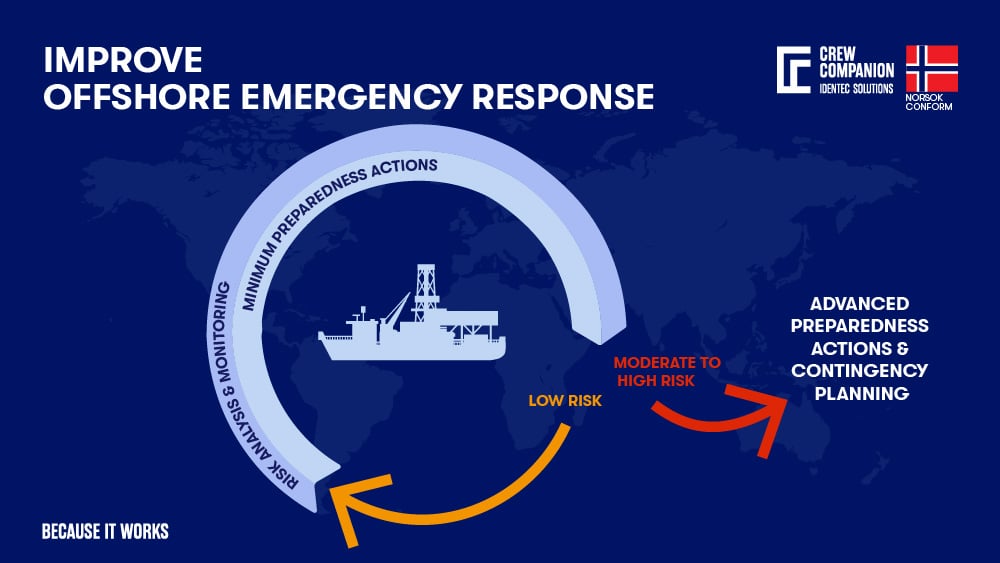

We mentioned above that the main objective of an Emergency Response Plan is to improve the speed and volume of assistance delivered immediately after the onset of an emergency. It not only provides practical guidance to assist offshore and onshore emergency teams but also prepares accordingly to act independently (learn more about emergency response team jobs). Emergency Response Preparedness not only develops a shared understanding of hazards and risks but also asks for organisational multi-hazard preparedness and the availability of contingency plans.

One critical part of Emergency Response Preparedness (ERP) is risk management in general and risk analysis in particular. The UNHCR, for example, considers ERP to be the foundation of its emergency response plans. The risk analysis process identifies hazards that could trigger a crisis and ranks them by impact and likelihood. The risk ranking determines whether thresholds are low, medium, or high. The analysis informs planning, while monitoring ensures the process is responsive to emerging risks. In the best case, risk analysis and monitoring can detect an emerging crisis before it strikes.

When your risk monitoring suggests loss of the offshore installation is likely, the offshore emergency evacuation process will be triggered as early as possible. Any delay will result in increased safety risks. Therefore, you must ensure your evacuation system is optimal before you need it.

Optimal evacuation processes and systems will ensure that your personnel can be evacuated as quickly and safely as possible in case of an emergency. However, if the (planned) system is not functioning, the people present may be hindered or trapped, resulting in human casualties. Therefore, it is of the utmost importance to conduct evacuation assessments.

A typical evacuation analysis may include the following elements:

- A risk analysis, including accidental events that may require evacuation.

- Existing escape routes regarding their accessibility in different scenarios.

- Evacuation time under specific conditions (hazards, weather, and number of personnel).

- Lifeboat launching time and probability of a successful launch.

- The most favourable locations for mustering, lifeboats, and personal life-saving appliances (see also: Emergency response plan).

- The necessary capacity of offshore safety equipment.

- Evaluation of design.

Rig Safety: TAKEAWAY

Once risk analysis is done, prepare your crew for medium and high-risk scenarios. Address the most impactful ones and plan, test and evaluate your offshore emergency response through conducting training & drills. Compare results, test under different degrees of severity and difficulty, and eventually find the optimal supporting system for your EER process: What type of "e mustering" system do you need? Which zones must be accessible, and which ones are locked off? How do you keep the mustering list up-to-date? ...

Learn more about Emergency Response Management!

Glossary

Evacuation, Escape, and Rescue (EER) refers to the systems, procedures, and actions designed to ensure the safe removal of personnel from hazardous situations, particularly in offshore oil and gas operations. EER includes three key phases: escape, where individuals move away from immediate danger; evacuation, involving organised departure using lifeboats or helicopters; and rescue, where external teams assist stranded or injured personnel. Effective EER planning integrates safety drills, emergency equipment like lifeboats and immersion suits, and clear protocols to minimise risks. Regulatory standards ensure that EER measures are robust, reliable, and capable of handling extreme conditions like fire, explosions, or severe weather. (3)

Sources:

(1) Mohamed Shaluf, I. and Ahmadun, F. (2008), "An overview on the offshore emergency response planning in Malaysia", Disaster Prevention and Management, Vol. 17 No. 1, pp. 83-93. https://doi.org/10.1108/09653560810855892

(2) Ben Woodcock, Zachary Au: Human factors issues in the management of emergency response at high hazard installations, Journal of Loss Prevention in the Process Industries, Volume 26, Issue 3,

2013, Pages 547-557, ISSN 0950-4230, https://doi.org/10.1016/j.jlp.2012.07.002.

(3) https://www.hse.gov.uk/offshore/eer.htm

Note: This article has been updated on the 25th of August 2025. This article was partly created with the assistance of artificial intelligence to support drafting. The head image was generated by AI.

Author

Mark Buzinkay, Head of Marketing

Mark Buzinkay holds a PhD in Virtual Anthropology, a Master in Business Administration (Telecommunications Mgmt), a Master of Science in Information Management and a Master of Arts in History, Sociology and Philosophy. Mark spent most of his professional career developing and creating business ideas - from a marketing, organisational and process point of view. He is fascinated by the digital transformation of industries, especially manufacturing and logistics. Mark writes mainly about Industry 4.0, maritime logistics, process and change management, innovations onshore and offshore, and the digital transformation in general.

Related Articles

Related Product