RoRo cargo operations: Tech support for optimal logistics

| Written by Mark Buzinkay

No video selected

Select a video type in the sidebar.

RoRo cargo operations in a nutshell

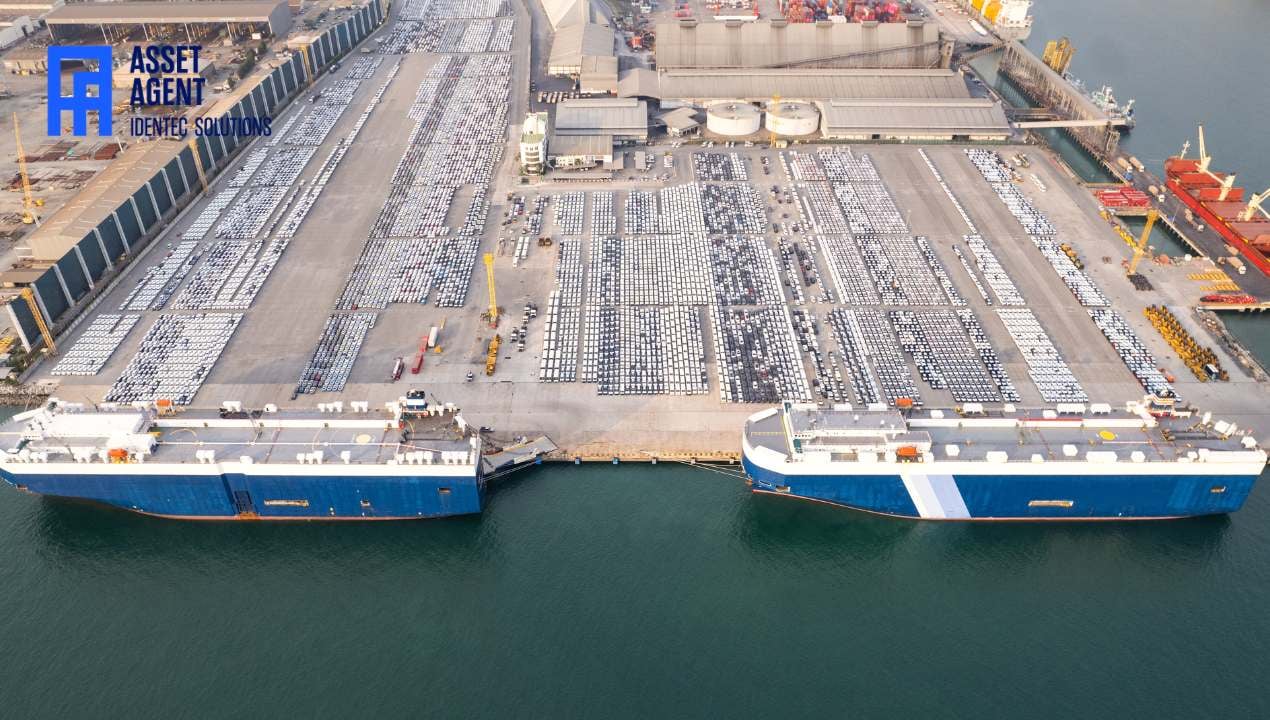

The global automotive industry relies heavily on efficient logistics to move vehicles from local manufacturing plants to worldwide markets. A critical component of this logistics chain is the Roll-on/Roll-off (RoRo) operation, a specialised method used extensively in an automotive port. RoRo operations, characterised by their efficiency and simplicity, involve driving vehicles on and off large cargo ships, bypassing the need for cranes or other heavy-lifting equipment.

As we delve into the inner workings of RoRo operations at car terminals, we highlight their processes and technologies. The focus is twofold: firstly, to provide a comprehensive overview of the RoRo transport process, and secondly, to explore the advanced technologies that have revolutionised these operations, particularly in vehicle identification and location.

A significant aspect of modern RoRo operations is managing thousands of vehicles efficiently, ensuring each is accurately tracked and located throughout its journey in the terminal. Traditional methods, while adequate to an extent, have given way to more sophisticated technological solutions. These advancements enhance operational efficiency and minimise errors, leading to a smoother, faster, and more cost-effective distribution process.

One such innovation is 'Asset Agent', a state-of-the-art solution to streamline RoRo operations. This system stands out for its ability to identify, locate, track, and update the status of assets in real-time, representing a significant leap forward in logistics management. By integrating cutting-edge technology into traditional RoRo operations, Asset Agent offers precision, efficiency, and real-time data.

As global demand for vehicles continues to grow and the automotive industry becomes increasingly complex, the role of efficient RoRo operations in car terminals cannot be overstated.

RoRo cargo: Process overview at the car terminal

Car terminals not only symbolise a knot in the supply chain, but they also play an essential role in the automotive industry, offering comprehensive services for both new and used vehicles. These services encompass transport, handling, technical treatment, and storage. Manufacturers often rely on logistics companies with extensive networks across Europe, North America, and other developed regions, utilising automobile terminals at key traffic junctions. Each vehicle undergoes a series of steps within this automobile logistics network, including collection from the manufacturer, multimodal transport to the terminal, and, eventually, delivery to dealerships.

Transport & Identification

Upon arrival at the terminal, each vehicle is immediately identified. Terminal staff typically do this either by pen and paper (an outdated process) or using mobile data entry devices (MDE) that can read barcodes. These barcodes are usually placed inside the vehicle, behind the windscreen, and are linked to the unique vehicle identification number (VIN). The VIN is crucial as it matches the car with its respective parking and technical treatment orders in the logistic IT system.

Storage Allocation

Once identified, the IT system assigns each vehicle a parking location based on predefined priorities. This location is within a designated storage area of the terminal, optimised for easy access, efficient use of space, and the defined next steps in the process.

Placing in Stock

Handling employees then move the vehicles to their assigned Parking locations. This step is critical in maintaining order and efficiency within the terminal, ensuring that each vehicle is easily retrievable for future processing.

Delivery Request

When a vehicle is ready to be moved from the terminal, a delivery request is initiated. This signals the start of the process to remove the vehicle from its parking location and prepare it for its next journey.

Removal from Stock

Following the delivery request, the vehicle is removed from its parking location. This is the first step in physically moving the vehicle from the terminal and toward its final destination.

Technical Treatment

Before the vehicle can be delivered, it may undergo various technical treatments. These treatments can include fueling, car washing, customising, tire changing, and other necessary services. The sequence and nature of these treatments are specified in the vehicle's technical treatment order.

Delivery

Finally, the vehicle is moved to the shipment area after all technical treatments are completed. Here, it is prepared for transportation to the automobile dealer. This final step marks the completion of the vehicle's journey through the car terminal, readying it for its final delivery to the customer.

How do you Identify and Locate Vehicles?

The efficiency of RoRo car operations in car terminals largely depends on the precision of vehicle identification and location. Given the high volume of vehicles processed daily, the challenge lies in accurately tracking each unit throughout its journey in the terminal to avoid time-consuming searches and vehicle reparking.

Accurate identification and precise location are critical for several reasons:

- Efficiency: Quick vehicle identification and location reduce processing times. Handling drivers know exactly where "their" cars are located, identifying them on the walk.

- Inventory Management: Accurate tracking ensures proper inventory control and space utilisation. Car park managers know in real-time exactly which car when arrived and what the status of that car is.

- Customer Satisfaction: Timely and accurate delivery of vehicles enhances customer trust and satisfaction.

Traditional methods, such as manual checks and paper-based tracking, are increasingly replacing more efficient, technology-driven processes. These modern methods are not only more reliable but also significantly faster, facilitating the management of a large number of vehicles with greater accuracy.

What Technologies Play a role in Vehicle Identification?

While traditional methods relied on visual inspections and manual data entry, modern solutions use:

- VIN: Reading (or scanning) the Vehicle Identification Number is the straightforward solution. The disadvantage here is that the VIN is not always as accessible.

- Barcode systems: Barcodes, typically placed behind the windscreen, are scanned to retrieve the vehicle's data. Disadvantage: Barcodes (or QR codes) must first be printed out.

- RFID tags: Radio-frequency identification (RFID) tags offer a more advanced method, enabling quicker and more accurate identification. The disadvantage is that you need to pair the tag with the VIN first.

- Pick-by-light: Active RFID tags enable adding a pick-by-light system to each vehicle, making identification much easier for the human eye.

These technologies serve several key functions:

- Speeding the process: Automating the identification process reduces the time taken per vehicle.

- Reducing errors: Technology minimises human errors, ensuring more accurate tracking.

- Integration with IT systems: Automated identification systems seamlessly integrate with logistics IT systems, enabling better data management and analytics.

Advanced Technologies in Vehicle Location

The precision in locating vehicles within the expansive grounds of a car terminal is pivotal for operational efficiency. Modern technology, including Chirp, GPS, WiFi, RFID, and others, can play a crucial role in enhancing this aspect of RoRo operations.

Diverse technology stack for location tracking:

- Ultra-Wideband (UWB): UWB offers highly accurate, real-time location tracking by measuring the time it takes for a radio wave to travel between the vehicle and a receiver. Its precision in pinpointing locations makes it invaluable in densely packed terminals.

- WiFi: Utilized for location tracking through signal triangulation, WiFi can determine the position of a vehicle within the terminal. While not as precise as UWB, it is a cost-effective solution for less dense areas.

- RFID (Radio-Frequency Identification): RFID tags attached to vehicles interact with readers placed around the terminal, offering a reliable method for tracking vehicle movement and location.

- Chirp Spread Spectrum: This technology transmits a chirp signal that spreads across a wide frequency band. Chirp signals' unique properties, such as resistance to interference and the ability to measure distances accurately, make them well-suited for vehicle tracking in busy environments.

- GPS (Global Positioning System): This is the preferred solution for outdoor areas because no own readers/satellite infrastructure is needed.

Enhancing RoRo cargo operations through location technologies

- Real-Time Updates and Precision: Technologies like UWB and Chirp provide exact vehicle locations in real-time, drastically reducing the time staff spend searching for specific vehicles.

- Scalability and Flexibility: GPS, WiFi and RFID offer scalable solutions that can be adjusted based on the size and layout of the terminal, providing flexibility in operation management.

- Automated and Efficient Storage Management: By integrating these technologies, car terminals can automate the allocation and optimisation of storage spaces, leading to better space utilisation and streamlined operations.

- Improved Coordination and Safety: Enhanced tracking capabilities strengthen the coordination among staff, reducing vehicle handling times and increasing safety in the terminal.

By incorporating one or multiple of these technologies, car terminals can significantly boost the efficiency and accuracy of their vehicle location systems. This integration not only streamlines the RoRo process but also paves the way for future innovations in automotive logistics management.

Asset Agent can do it all

Each car terminal has its own set-up, size, business processes and logistics specifications. Some have a huge car park; others use garage buildings to store their vehicles. There are inland car terminals for temporary storage, and there are intermodal transhipment hubs along the sea. Car terminals can be giant customisation stations or just parking lots. It is essential to understand the tasks and objectives to improve processes in terms of efficiency, cost-effectiveness and speed of operations. And you need the right solution to adapt to what the process needs.

Asset Agent is a modular solution offering diverse technologies for different tasks. Pinpoint location accuracy indoors, pick-by-light functionality when you need it, and automatic car status updates based on zones are achievable using Asset Agent transponders. Suppose you prefer no additional hardware at all. In that case, Asset Agent "light" combines geofencing, GPS-location tracking, and manual scanning techniques for a low-cost system that offers the same business logic as the full-stack solution. In either case or when you combine both for the best of your process set-up, Asset Agent provides job allocation for your workers, job documentation for every car and task, records for potential damage claims, automatic shipment manifests and loading sequences. It interacts with 3rd party software like Warehouse Management Systems or Terminal Operating Systems through standardised interfaces.

Takeaway

In the world of RoRo cargo operations at car terminals, a blend of traditional methods and cutting-edge technology ensures the efficient management of vast vehicle inventories. Car terminals, vital nodes in the automotive supply chain, handle comprehensive services from transport and technical treatment to storage. The key to their success is the seamless integration of technology in every step - from transport and identification to the final delivery. By adopting technologies like UWB, WiFi, RFID, and Chirp for location tracking, terminals effectively manage the complex logistics involved. Each technology brings unique advantages, whether it's the pinpoint accuracy of UWB or the flexibility of WiFi and RFID systems. Asset Agent emerges as a versatile solution that is adaptable to diverse terminal setups and processes, offering hardware-based and light options for optimal operational improvement. If you want to learn more about Asset Agent functionalities, business cases and pricing models that also include a subscription-based model, don't hesitate to contact us through the form below.

Glossary

Mobile Data Entry (MDE) refers to the use of mobile devices—such as smartphones, tablets, or handheld terminals—to input, access, and manage data in real time, often within industrial, logistics, or field service environments. MDE improves efficiency, accuracy, and responsiveness by enabling users to interact with systems directly from the point of activity. It supports digital workflows, reduces paperwork, and enhances data availability.(2)

Reference:

(1) https://www.ecgassociation.eu/

(2) Gonzalez, R., Gasco, J., & Llopis, J. (2010). Information systems outsourcing reasons and risks: a new assessment. Industrial Management & Data Systems, 110(2), 284–303.

Note: This article was updated on the 26th of March 2025

Author

Mark Buzinkay, Head of Marketing

Mark Buzinkay holds a PhD in Virtual Anthropology, a Master in Business Administration (Telecommunications Mgmt), a Master of Science in Information Management and a Master of Arts in History, Sociology and Philosophy. Mark spent most of his professional career developing and creating business ideas - from a marketing, organisational and process point of view. He is fascinated by the digital transformation of industries, especially manufacturing and logistics. Mark writes mainly about Industry 4.0, maritime logistics, process and change management, innovations onshore and offshore, and the digital transformation in general.