Safe mining practices: 5 safety tips

| Written by Mark Buzinkay

No video selected

Select a video type in the sidebar.

Table of contents:

- What Are The Most Common Mining Threats?

- What Are Safe Mining Practices?

- Safe Mining Practices: Emphasis On Training And Technological Development

- FAQs

- Takeaway

- Glossary

What are the most common Mining Threats?

Mining is an industry that has long captured the imagination of humankind, delving into the Earth's depths in search of precious resources. However, as the quest for valuable minerals and ores continues, it is crucial to shed light on the numerous underground threats jeopardising miners' safety and well-being. According to the International Labour Organisation, while mining accounts for 1% of the global labour force, it causes 8% of fatal accidents. In this article, we delve into the critical challenges faced by miners and explore the measures being taken to mitigate these risks.

- Geotechnical Hazards: One of the most significant threats to miners is the instability of the geological environment in which they operate. Rockfalls, cave-ins, and landslides pose substantial risks to miners' lives. Weak rock structures, unpredictable ground movements, and hazardous gases contribute to the ever-present danger. To address these hazards, mining companies are implementing robust geotechnical assessments, deploying advanced monitoring systems, and investing in developing new technologies to enhance early warning systems and improve structural integrity.

- Respiratory Health Risks: Underground mining operations often expose workers to harmful airborne particles and gases. The inhalation of dust, silica, coal dust, and toxic gases like radon can lead to various respiratory diseases, including silicosis, black lung disease, and lung cancer. Stringent ventilation systems, personal protective equipment (PPE), and routine health monitoring are critical for safeguarding miners against these risks. Additionally, ongoing research and development in filtration technologies and better ventilation designs aim to minimise exposure to harmful substances.

- Underground Fires and Explosions: Mining activities use heavy machinery, explosives, and flammable substances, making underground fires and explosions a significant concern. Methane gas accumulation, inadequate ventilation, and improper handling of explosive materials can all contribute to catastrophic incidents. Rigorous training programs, continuous monitoring of gas levels, strict safety protocols, and implementation of innovative fire suppression systems are crucial to prevent and manage such emergencies effectively.

- Physical and Mental Health Challenges: Working in confined spaces, often in remote and isolated locations, affects miners' physical and mental well-being. Extended periods away from family, irregular sleep patterns, and the physically demanding nature of the job can lead to fatigue, stress, and a higher risk of accidents. Mining companies are increasingly focusing on comprehensive health and wellness programs, offering support services, and promoting mental health awareness. Regular breaks, access to counselling, and initiatives to improve work-life balance are being prioritised to ensure the overall well-being of miners.

- Striving for Sustainable Mining: While addressing immediate threats is vital, the mining industry is also shifting its focus towards sustainable practices. Environmental concerns, such as soil and water contamination, deforestation, and the depletion of finite resources, are challenges that must be met head-on. Adopting sustainable mining practices, implementing responsible waste management, and investing in renewable energy sources are crucial steps towards minimising the industry's environmental impact and creating a more sustainable future.

In conclusion, the threats miners face in the depths of the Earth are numerous and varied. From geotechnical hazards to respiratory health risks, underground fires, and mental well-being challenges, ensuring the safety and security of miners demands unwavering attention and continuous improvement. In collaboration with regulatory bodies, the mining industry must remain committed to implementing stringent safety measures, advancing technology (see also: mine monitoring), and fostering a culture of vigilance to protect those who venture into the depths to unlock the Earth's treasures.

What are Safe mining practices?

In the dynamic and often hazardous world of mining, creating a safety culture is not just an option; it is an imperative for ensuring the well-being of miners and maintaining a safe work environment. The concept of safety culture encompasses a collective set of beliefs, values, attitudes, and perceptions within an organisation, which establishes a shared commitment to safety and a drive to minimise harm.

1. Assess hazards

Assessing the hazards may be the most critical step in mitigating safety risks. Putting together a plan is a good starting point. Such a plan indicates:

- the nature of the principal mining hazard

- how it relates to other threats at the mine

- the analysis methods used in identifying the mining hazards

- a record of the risk assessment conducted concerning the mining hazards

- a description of all control measures to be implemented to manage risks to health and safety associated with the principal mining hazards

- a description of the arrangements in place for providing to workers the information, training and instruction required about the main mining hazard

Insights from a plan like this influence drilling design and blasting operations. Careful investigation of the rock characteristics, stresses and probable aftermath can decrease the unknowns and improve the sequence of events.

Using the right software makes it possible to display the various outcomes of a proposed plan. Digital twins are an ideal way to explore a variety of scenarios.

2. Maintain a culture of safety

A robust (miner) safety culture sets the foundation for a safe work environment by establishing high standards for safety processes and procedures. It goes beyond merely complying with regulations and protocols; it ingrains a proactive approach to identify and mitigate potential risks. By making safety an integral part of the organisational DNA, mining companies emphasise the importance of each employee's well-being and make it a shared responsibility across all levels.

One of the key advantages of implementing a positive safety culture is the promotion of commitment and accountability among the workforce. When safety is prioritised and valued, employees develop a personal investment in ensuring their own safety and that of their colleagues. Safety becomes ingrained in daily operations, and checklists and protocols are seen as essential tools rather than burdensome tasks. Workers understand that their actions directly impact the well-being of everyone involved, leading to a collective effort to maintain a safe work environment.

Encouraging open communication and feedback from workers is another crucial aspect of building a strong safety culture. Empowering employees to voice concerns, report hazards, and suggest improvements creates a better working environment. Their firsthand experiences and insights can uncover potential safety hazards or gaps in existing protocols. By actively involving workers in the safety decision-making process, mining companies can tap into their expertise, enhance safety measures, and foster a culture of continuous improvement.

Moreover, a positive safety culture not only reduces the likelihood of accidents and injuries but also enhances overall operational efficiency. When safety practices are deeply ingrained, they become an integral part of standard operating procedures, seamlessly integrated into daily work routines. Workers are more likely to follow established safety guidelines, leading to increased productivity and minimised downtime due to accidents or incidents. Additionally, a safety-conscious workforce instils confidence in stakeholders, demonstrating a commitment to responsible mining practices and promoting a positive industry reputation.

Creating a strong safety culture requires a multifaceted approach that involves leadership commitment, comprehensive training programs, ongoing communication, and continuous reinforcement. Mining companies must invest in comprehensive safety training to equip employees with the necessary knowledge and skills to identify and address potential hazards. Leadership plays a vital role in setting the example and fostering a culture of safety through consistent messaging and visible commitment to safety practices (learn more about conducting toolbox talks on safety).

3. Wear Personal Protective Gear

Personal protective equipment, commonly known as PPE, serves as a vital shield to minimise exposure to various hazards in the mining industry. From gloves and steel-toed footwear to eye protection, hearing devices, hard hats, respirators, and full-bodysuits, PPE plays a crucial role in safeguarding the well-being of miners. This article highlights the significance of PPE in mining operations and emphasises the importance of proper usage and adherence to safety protocols.

Hard hats are among the essential components of PPE, designed to protect miners from severe injuries, particularly from rockfall incidents. Falling rocks and debris constantly threaten underground and surface mining environments. A properly fitted and sturdy hard hat acts as the first line of defence, reducing the risk of head injuries and potential fatalities. Workers must wear their PPE, including hard hats, before entering hazardous zones, ensuring they are prepared for the potential dangers that lie ahead.

Beyond hard hats, the range of PPE available for miners is extensive and tailored to address specific risks. Gloves shield hands from cuts, abrasions, and chemical exposure, while steel-toed footwear protects against heavy objects, falling debris, and accidental impacts. Eye protection, such as safety glasses or goggles, shields against dust, flying particles, and hazardous chemicals. Protective hearing devices, including earplugs and earmuffs, safeguard miners' hearing against excessive noise levels, preventing long-term damage.

Respiratory protection is paramount in environments where miners are exposed to harmful gases, dust, or airborne contaminants. Respirators, including filtering facepiece respirators (commonly known as masks) or self-contained breathing apparatus (SCBA), ensure miners breathe clean air, reducing the risk of respiratory diseases and long-term health complications.

In certain mining activities involving chemicals or hazardous substances, full-body suits provide comprehensive protection against skin contact, spills, or splashes. These suits are designed to create a barrier, minimising the risk of chemical burns, absorption of toxic substances, or other skin-related injuries. Mining companies must define the specific PPE requirements for each activity, ensuring that workers are equipped with the appropriate gear to address the associated hazards.

Regular inspection and maintenance of PPE are essential to ensure its effectiveness. Miners should replace any defective or damaged clothing or equipment immediately, as compromised PPE can jeopardise their safety and render them vulnerable to injuries. Adherence to safety protocols and procedures related to PPE usage must be a priority, and companies should provide regular training and reinforcement on the correct usage, maintenance, and storage of PPE to all workers.

The significance of PPE goes beyond individual protection; it contributes to creating a safety culture within mining operations. When miners see PPE as a mandatory and non-negotiable aspect of their work, it reinforces the importance of safety and establishes a shared responsibility for everyone's well-being. PPE serves as a tangible reminder of the potential hazards present in the mining environment and encourages workers to stay vigilant and proactive in mitigating risks.

Further reading: Mine Safety - Why digital management?

4. Keep your equipment in perfect shape

Neglected equipment will deteriorate quickly in harsh environments like a mine. Malfunctioning can lead to loss of control or open up dangers. Follow recommended maintenance from the manual, keep used equipment clean and store it properly after use.

One important rule is to inspect equipment regularly, replace essential parts when necessary and ensure regular lubrication to restore them to their former quality. Proper upkeep can increase equipment life, posing less danger to miners.

5. Improve visibility

5. Improve visibility

In underground operations, visibility is always an issue. Dark pathways and work areas can jeopardise you because it's more likely for you to make mistakes with low visibility. Eliminating intersections whenever possible, so drivers only have to look one way, is a good start to avoid hazards. If needed, implementing intersection protocols is a good idea, like following a four-way stop rule where the person on the right always goes first or where an operator with a full load always has the right of way.

In general, underground illumination can solve the problem. Ensure personal lighting devices and stationary lamps can withstand all weather conditions. This can offer constant light sources and keep mining crews from unexpected blackouts. In addition, working headlights on machinery and mobile equipment can alert drivers to nearby personnel, preventing hazardous collisions.

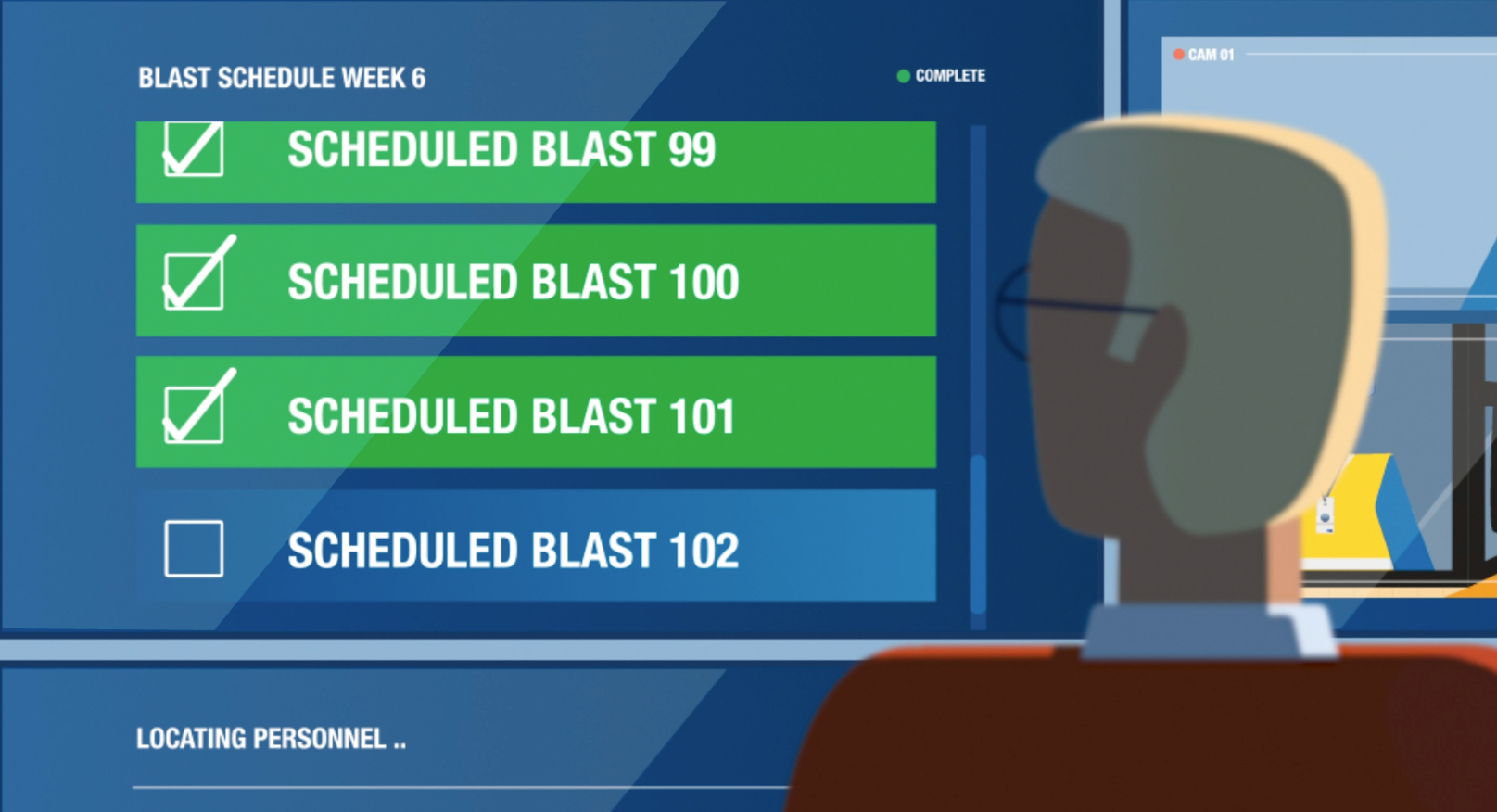

When it comes to pre-and post-blasting procedures, visibility is essential. You don't want anyone close to an explosion or being exposed to gases. Therefore, visibility of where your workforce is vital for safe mining operations: visibility is best achieved by an automated miner tracking system.

Safe Mining Practices: Emphasis on Training and Technological Development

Besides the critical steps mentioned before, continuous training and embracing the latest technological advancements are similarly very important for improving mine safety. Constant education programs expose miners to the safest working practices and emergency response procedures. Regular safety drills and refresher courses help ingrain such practices into daily routines, thereby putting a culture of preparedness and vigilance into place. Besides, the exploitation of advanced technologies like automation, real-time monitoring systems, and remotely controlled machinery greatly reduces exposure to hazardous conditions by minimising the need for human presence in areas of hazard. Other innovations, such as drone surveillance for geological assessments and AI-driven predictive maintenance systems, further make for a safer mining environment by pointing out the potential dangers before they show up. By incorporating comprehensive training with technological advancement, the mining industry can endlessly reduce accidents and improve the general safety of mining as well as the effectiveness of operations.

FAQ

What are the primary hazards addressed by safety mining practices?

Safety mining practices design and implement processes to mitigate a range of primary hazards that include geotechnical hazards, such as rockfalls and cave-ins; respiratory health linked to inhaling harmful airborne particles and gases; potential fires and explosions underground; and physical and mental challenges brought about as a result of high-demanding work.

How can safety mining practices help protect miners from respiratory health risks?

Safety mining practices prevent miners from having respiratory health risks by installing stringent ventilation, providing PPE, including respirators, and monitoring health status regularly. These measures are directly go in line with the reduction of inhalation of hazardous dust, silica, coal dust, and toxic gases to man, thus preventing silicosis and lung cancer.

Takeaway

By embracing safe mining practices and prioritising the well-being of miners, the mining industry can create a safer work environment and mitigate the risks inherent in mining operations. Through continuous improvement, training, and technological advancements, the industry can strive towards a future where mining is not only productive but also safe and sustainable.

Delve deeper into one of our core topics: Mining Safety

Glossary

Self-Containing Breathing Apparatus (SCBA) is a kind of respirator put together to provide breathable gas from an integrated gas cylinder, ensuring autonomy in environments that pose immediate dangers to life or health. Commonly used in firefighting and industrial settings, the term "self-contained" emphasises its independence from external sources of breathable gas, such as those delivered through a long hose. SCBAs are also called industrial breathing sets, and some models are called Compressed Air Breathing Apparatus (CABA) or simply breathing apparatus (BA). Various informal terms are used for these contraptions, including air pack, air tank, oxygen cylinder simply "pack".

Personal protective equipment (PPE) is equipment worn to minimise exposure to hazards that cause serious workplace injuries and illnesses. These injuries and illnesses may result from contact with chemical, radiological, physical, electrical, mechanical, or other workplace hazards. Personal protective equipment may include items such as gloves, safety glasses and shoes, earplugs or muffs, hard hats, respirators, coveralls, vests and full-body suits.

Sources:

(1) https://safetyiq.com/insight/safety-in-mining-why-its-important-and-how-to-get-it-right/

(2) https://en.wikipedia.org/wiki/Self-contained_breathing_apparatus

(3) https://www.osha.gov/personal-protective-equipment

Note: This article was updated on the 5th of August 2025. This article was partly created with the assistance of artificial intelligence to support drafting. The head image was generated by AI.

Author

Mark Buzinkay, Head of Marketing

Mark Buzinkay holds a PhD in Virtual Anthropology, a Master in Business Administration (Telecommunications Mgmt), a Master of Science in Information Management and a Master of Arts in History, Sociology and Philosophy. Mark spent most of his professional career developing and creating business ideas - from a marketing, organisational and process point of view. He is fascinated by the digital transformation of industries, especially manufacturing and logistics. Mark writes mainly about Industry 4.0, maritime logistics, process and change management, innovations onshore and offshore, and the digital transformation in general.