Underground safety by zone coverage

| Written by Mark Buzinkay

No video selected

Select a video type in the sidebar.

Mining is a hazardous business in terms of workplace safety. Thanks to the myriad of HSE initiatives, working in mines got safer but "zero harm" has still to be achieved. Preventive measures like different mine design, excavation monitoring, implementation of autonomous systems and AI, explosion-proof equipment improved conditions but need a backup system in the event of an emergency.

US mining industry’s total fatalities for 2024 have risen to 28 following three deaths in November. MSHA has not reported any fatalities on its website since 18 December, with the last recorded fatality occurring on 27 November. The industry's record-low fatalities mark is 25, set in 2016. In November, three mining fatalities matched 2022’s total. The first occurred on 5 November at a Texas crushed stone operation due to a powered haulage accident. The second, on 16 November, happened at an Ohio sand and gravel site and involved machinery. The third, on 27 November, was at an Ohio underground salt mine, also classified as a powered haulage accident. Powered haulage and machinery remain the leading causes of mining fatalities in 2024, with 12 and four deaths, respectively. Other causes include falls, electrical incidents, and fires. Despite a promising start, seven deaths in August and six in September put a record-low fatality year in doubt. (3)

Safety assistance systems have different layouts and designs. They not only differ by the technical set-up but also what they are capable to do. One aspect of a miner safety tracker solution is the idea of zone coverage. What does this mean? In general, zone monitoring focus on a specific zone and shows who is in that zone. This is different from the idea to track personnel wherever it is.

What are The difficulties of monitoring personnel underground?

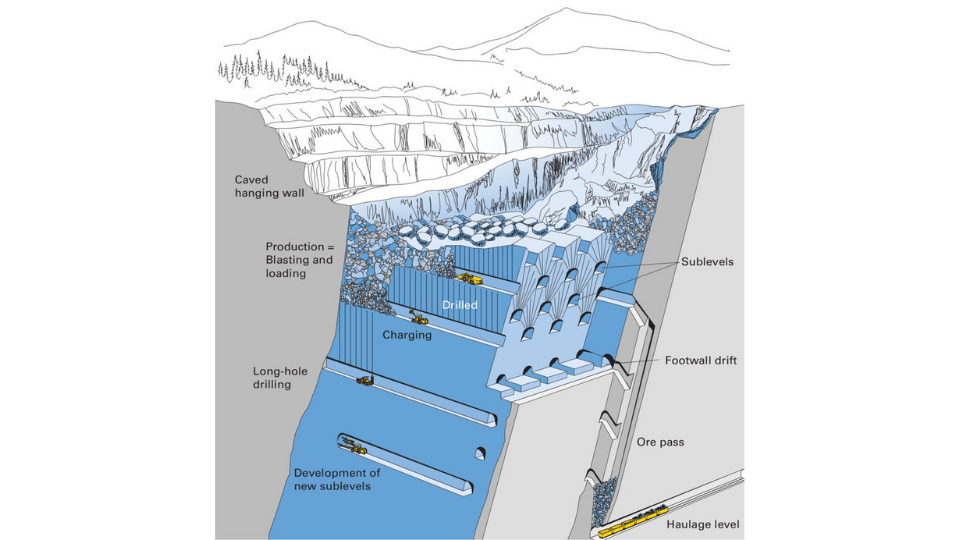

Typically, a mine consists of several distinct areas: the entrance or access points, ramps for trucks and other equipment, blasting & loading levels, haulage level, exploration and drilling areas, ore passing, crushing and transporting installations as well as the above-ground production plant. Underground ramps and tunnels can sometimes grow to a network of several hundred kilometres in total. After a level has been exploited, it will be filled with waste material and abandoned. A mine is continuously moving - deeper and further with all necessary installations for production, transport and safety.

Monitoring miners underground is challenging because a mobile phone network or GPS is unavailable. Alternatively, operators create their own network. Intuitively, many think of a WiFi signal which would operators enable to locate a device within a certain radius of a specific WiFi router. The idea is feasible, but with one big disadvantage: you have to cover hundreds of kilometres, permanently installing and uninstalling infrastructure to keep with the progress of the mine, which is labour-intensive and costly.

Learn how the Chile mine disaster transformed an entire sector!

Learn more about typical scenarios to use miner tracking solutions.

Why is Zone coverage the better solution for underground safety?

The better option is to cover zones. Covering zones means monitoring the access to zones. Let's say you have ten sub-levels of each 1 km length. Instead of putting fibre and WiFi routers along 10km underground tracks, you only add reading devices at every sub-level entrance. By this, you will always know how many people entered, are still in a specific zone or left it. Workers equipped with transponders enable the system to locate them continuously. In case of an emergency, the rescue coordinator can immediately identify people in a zone at risk and act accordingly.

A safety assistance solution is needed that offers 100% reliability. In the case of an explosion, water breach, rockfall, vehicle accidents, cables of a WiFi system can get disrupted and are not available anymore. The chances this happens are higher the longer the cable network is. Reading devices of a zone monitoring system are connected by cable to a much shorter extent. These connections follow the main levels and ramps which are better maintained and monitored.

The zone-cover approach has another advantage: it can be used to grant or deny access to certain sections or the mine itself. Read more about mine access control with Crew Companion here.

The other big advantage of zone coverage is its configurability to different configurations of mines and changes in operations. With the continuous changing nature of mining operations, new tunnels, shafts, and work zones are being added, while others are taken out of commission. Conventional tracking systems need massive reconfiguration and installation of new infrastructure; this adds to costs and provides more downtime. This information, however, can easily be reprogrammed or changed to add new areas in the case of zone coverage as development takes place. This flexibility improves operational efficiency and ensures that safety protocols are the best and most up-to-date possible, whether in an expanding or a contracting mine.

Zone coverage systems, as well, can integrate with any other advanced technologies to further improve underground safety. For example, integration with real-time environmental monitoring systems will allow zone coverage to instantaneously detect hazardous conditions such as gas leaks, high temperatures, or excessive dust levels. Should such conditions be identified within a specific zone, automatic warning will be triggered to all people inside the area, and emergency procedures will be initiated. This will ensure much safer working conditions and minimize the response time in case of emergencies, reducing the potential for injury or death. The mining operations are becoming increasingly deeper and ever more challenging; therefore, such integrated safety systems as this one will be vital in saving underground workers' lives.

FAQ

What is zone coverage in the context of underground safety?

Zone coverage refers to a system of monitoring and tracking personnel within specific zones or areas of a mine. Instead of tracking every movement of miners throughout the entire underground network, zone coverage focuses on monitoring access to and movement within defined zones. This method provides real-time data on who is present in each zone, enhancing safety and allowing for quick responses in emergencies.

How does zone coverage differ from traditional tracking methods?

Traditional tracking methods often involve continuous monitoring of personnel using extensive networks like WiFi or GPS, which are difficult to implement underground. Zone coverage, on the other hand, simplifies the process by only requiring monitoring at the entry and exit points of specific zones. This reduces the need for widespread infrastructure, making it a more practical and cost-effective solution in the underground environment.

What are the key benefits of using a zone coverage approach?

Zone coverage offers several benefits, including reduced infrastructure costs, enhanced reliability, and the ability to quickly locate personnel during emergencies. By focusing on specific zones, the system is less prone to disruption from events like explosions or rockfalls, which can damage more extensive networks. Additionally, zone coverage can be integrated with access control systems to regulate entry into dangerous or restricted areas.

How does zone coverage improve emergency response in underground mines?

In the event of an emergency, such as a fire or explosion, knowing the exact location of personnel is crucial. Zone coverage systems provide real-time information on who is in each zone, allowing rescue teams to quickly identify and assist those at risk. This targeted approach can save valuable time and increase the chances of a successful rescue operation.

TAKEAWAY

The mining industry is of a high-risk and often unpredictable nature; therefore, underground safety has been of paramount consideration. The zone coverage approach is one such smart, efficient, and reliable solution to the challenge of tracking and monitoring personnel in hazardous environments. Zone coverage does not focus on the movement of each movement inside a mine but certain zones, hence cutting down infrastructure costs while increasing safety and emergency response capabilities. As the mining industry remains dynamic, zone coverage will be among the many creative measures taken to actualize the ultimate goal of "zero harm" to all workers.

Dive deeper, browse through our wide selection of articles and learn much more about miner safety!

Glossary

Charging - is the process of filling drilled holes with explosives to break apart rock in mining operations. The location, depth, and size of these holes are carefully determined by mining engineers based on geological surveys and calculations. Proper charging ensures controlled fragmentation, maximizing efficiency while maintaining safety. The quantity and type of explosives used are precisely measured to achieve the desired breakage. Once the holes are charged, the explosives are detonated, creating a powerful force that fractures the rock and causes it to collapse. This controlled blasting process facilitates easier extraction and transport of the broken material for further processing. (4)

Sources:

(1) Illustration from: Numerical Investigation of Caved Rock Mass Friction and Fragmentation Change Influence on Gravity Flow Formation in Sublevel Caving - Scientific Figure on ResearchGate. Available from: https://www.researchgate.net/figure/Sublevel-caving-method-layout-1_fig1_315912296

(2) https://www.researchgate.net/publication/333630631_Systems_Approach_to_Underground_Safety

(3) https://www.pitandquarry.com/mine-fatalities-near-all-time-low-as-2024-approaches-finish/

(4) https://www.mining-technology.com/sponsored/understanding-charging-and-blasting-solutions-for-mines-and-tunnels/

Note: This article was updated on the 14th of February 2025

Author

Mark Buzinkay, Head of Marketing

Mark Buzinkay holds a PhD in Virtual Anthropology, a Master in Business Administration (Telecommunications Mgmt), a Master of Science in Information Management and a Master of Arts in History, Sociology and Philosophy. Mark spent most of his professional career developing and creating business ideas - from a marketing, organisational and process point of view. He is fascinated by the digital transformation of industries, especially manufacturing and logistics. Mark writes mainly about Industry 4.0, maritime logistics, process and change management, innovations onshore and offshore, and the digital transformation in general.