Port Automation Addressing challenges

Four ways to improve your container terminal productivity

Container terminals are critical knots in the worldwide supply network. At the same time, they are expensive, and resources such as geographical location, space, hinterland connection, and knowledgeable workforce are limited and must be managed wisely. That's why container terminal productivity plays such a vital role.

Areas of improvement are manifold and should be chosen where the impact is critical and offers a good ROI. Port automation of processes is technically feasible and eliminates costly human errors but should offer enough flexibility to handle exceptions.

Drug Trafficking and Container Terminal Safety

Shipping and law-enforcement officials say they believe about a third of cocaine cargoes from South America are moved around the world on commercial ships. Ship and terminal operators are under pressure to deliver vast amounts of cargo on time, and the rule of thumb around the world is that only one in 10 containers gets checked.

This arms race between drug smugglers and container terminal operators continues. Drug smugglers can find opportunities to penetrate the security concepts successfully and conduct smuggling to the profitable markets of Europe and North America in high quantities. Law enforcement is unable to stop this and acknowledges that there is only one way to control the number of narcotics flooding the markets effectively: to make it complicated and costly for the cartels to operate their supply chain.

This is the first half of a series about narcotics, container terminal safety and countermeasures through port automation.

Port Automation: What is operations planning?

Container terminals in seaports constitute essential connections between sea and land in the global supply chain. Consequently, these logistics facilities face an increasing demand for service capacity, as reflected by a tremendous growth in the worldwide container transshipments per year: 815.6 Mio TEUs of containers were handled in ports alone in 2020 (UNCTAD).

Container terminal reliability is the essential ingredient of a thriving port. But a terminal is faced with a complex set of variables that influence the outcome of everyday operation. Operational planning is a process that systematically takes all aspects of terminal assets into account and creates the most feasible and efficient plan to manage discharging and loading ships.

Ports Development With Sustainability In Mind

Environmental sustainability and port development is a growing concern among governments, international agencies, and business sectors across the globe today. It is essential to ensure that port development doesn't erode the quality of our environment and instead seeks to promote sustainable growth and development.

In this article, we will examine how ports development can increase sustainability according to the UN's Sustainable Development Goals (SDGs). We will explore the impact of port automation on economic, environmental, and social sustainability and offer a range of solutions to help promote sustainable port development.

Port Automation and Green Port Initiatives

The shipping industry is a major contributor to global emissions, but it is also one of the most promising sectors to reduce its environmental footprint. The key to improving the sustainability of the shipping industry lies in green port initiatives.

Green port initiatives provide a range of measures and measures to reduce emissions and make operations more efficient, with the end goal of creating a more sustainable shipping industry. In this article, we'll take a look at what green port initiatives are and how port automation can contribute to a sustainable shipping industry.

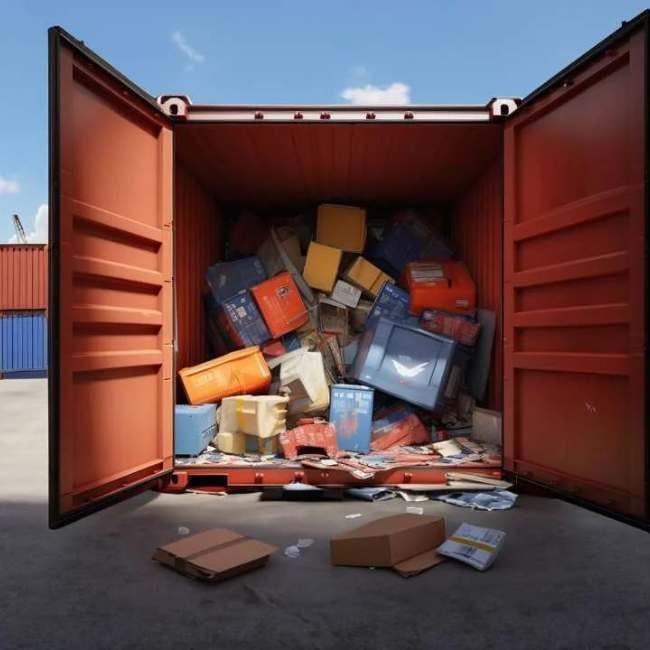

Port Automation and Stolen Cargo

Container terminals play a central role in the global supply chain. 90% of world trade is carried out via shipping, which means that this 90% of world trade also stops at a container port at least twice on its journey. However, their significance also makes container terminals vulnerable to cargo theft. In this article, we look into what is stolen, why it is stolen and what is or can be done about it with the help of port automation.

Port Automation and Jobs

It is a long way from the ports of the past, in which ships often had to stay longer than they were at sea, and a large number of workers loaded the goods onto the vessels or discharged the cargo with arduous physical exertion.

New technologies have alleviated or completely taken over many of these activities. Traditional jobs died out, and new ones appeared. But what always remains is the pride that these people rightly have in their work, which does nothing less than keep global trade going. Whoever continues to do the hard work in an often harsh environment today also deserves technological solutions that take their safety into account.

Port Automation and Container Damage Codes

Container damage is an ongoing challenge in the hustle and bustle of global trade. This damage can have a significant financial impact, disrupt supply chains and pose a security risk.

Therefore, it is crucial for the actors involved to understand the causes and consequences of the damage and to pursue remedial strategies. The key is to speak a common language called container damage codes.

This post gives you an overview of container damage causes and the corresponding codes.

The complete Container Damage Checklist

On the often thousands of kilometre-long routes that containers travel, numerous risks are present. Some are due to environmental conditions, others to the way they are handled. Understanding these risks is crucial for the safety of the cargo and the efficiency of the transportation process.

There are ways and technologies to avoid many of the risks. Our container damage checklist is intended to raise and deepen understanding of the causes of damage and the subsequent risks and provide instructions on how to avoid them altogether.

Port Automation & Dangerous Goods

Dangerous goods transport across international waters is a delicate task. Each shipment requires its own combination of protocols, specialised equipment, and strict handling requirements to ensure these high-risk items get safely from sender to recipient.

In this article, we'll cover all the types of dangerous goods, how they must be labelled and stored, and what measures must be taken to transport them safely.

Port Automation & Development

Automation is redefining port development and offering immediate solutions to complex challenges. The ongoing trend towards ever-increasing trade volumes is putting pressure on container terminals, suffering from overload, congestion and labour shortages.

Automation solutions are proving to be the tools that streamline operations to increase efficiency and sustainability. Whether it involves planning a new port or modernising an existing one, these solutions deliver success from the day they are first deployed.

Port Automation and WHS

The complex operation of container terminals poses significant risks to the health and safety of its employees. Owners and employers are increasingly being held accountable when incidents occur.

A significant push in this direction is being made in Victoria, Australia, with the workplace manslaughter legislation. The personal responsibility outlined in the law underlines the critical role that proactive safety management plays in reducing risk and promoting a safety culture.

Narcotics, Container Terminal Safety and the Rise of Technology

When IDENTEC SOLUTIONS set out on the journey of bringing a traditional Position Detection System (PDS) to the market, we imagined the main motivating factors for purchasing would be keeping 100% yard stowage accuracy and the elimination of CHE operators' keystrokes.

Ports and liners remain targets for organized crime to use the shipping container to distribute contraband material, whether illegal drugs, weapons, counterfeit goods or sanctioned commodities.

Port Automation: Improving terminal operations

Terminal Tracker is a crucial ingredient to create a semi-automated port. The objective is to improve container terminal operations to their full potential. Our video explains the principles, and the TTI Algeciras use case shows how things are done in reality.

In just ten years, TTI Algeciras became one of the Top10 performing container terminals worldwide. Their relentless focus on process optimization and a committed workforce helped them become a very successful player in the international shipping industry.

How is semi-automation increasing productivity?

One-third of container terminal operators see port automation as a way to increase productivity by up to 50%. At the same time, about one fifth believe that automation could cut operational costs by more than 50%.

Lean, Six Sigma, Agile, and other continuous improvement methodologies embrace smart automation. However, not everything can be automated, nor should it be. The lean journey needs to be adopted, not just automation alone. As in other industries, excessive port automation means less flexibility within container terminals due to amortisation.

But less flexibility for operational planning, new scenarios that have to be previously planned, more difficulty to react when exceptions occur must be taken into account when expecting higher productivity. A semi-automated port is in the most cases the way to go.

Unreported Container Damage: How to achieve fewer claims in Ports

The efficiency of terminal operations depends on whether supply and demand can be adequately planned and handled. A big part of this process is asset management and scheduling. It relays on accurate and up to date information on all your assets. This can be almost impossible if unscheduled breakdowns or damages get out of control.

Tracking unreported damages can be pretty challenging; reviewing, collecting, and analysing historical data from various sources is labour-intensive, time-consuming - and prone to errors. Often made impossible due to the lack of available and accurate data.

To investigate unreported damages, you need objective, rich data. With a solution like Terminal Tracker that interacts with your TOS, you bring port automation to a new level.

Sustainability and the Supply Chain: Container Terminals

This post will discuss container terminals' sustainability challenges, examine how they respond to them, and explore ways to integrate sustainability into their operations better. It will also consider how this improved sustainability performance can benefit businesses and consumers. Finally, it will look at how technology can help container terminals make their operations more sustainable.

Port Automation and the Green Port Concept

The concept of a green port is gaining momentum in the shipping industry. This sustainable approach to managing cargo operations can help make container terminals more efficient and profitable, while also reducing their environmental footprint.

In this blog post we'll explore the different definitions of and initiatives for Green Port concepts, enabling container terminal managers to embrace eco-friendly operational strategies to maximize profits and reduce their impact on the environment. Come along with us and learn how you can incorporate the green port concept into your daily operations!

Port Automation Trends

In recent years and decades, the global logistics industry has seen a shift towards port automation in container terminals. Advancing technologies and the demand for efficient and sustainable supply chain solutions are leading port terminals to increasingly rely on automated solutions that optimise operations, improve productivity and increase competitiveness. A variety of solutions are already in the starting blocks to begin their triumphal march through the world's ports in the next few years.

Port Automation Safety

The maritime industry is in the midst of a transformation driven by the increasing integration of technology into operations, redefining health, safety and environmental (HSE) practices in ports.

This article traces the evolution of port security and explains how semi-automation is the next logical step to protect workers and optimise operations. Learn how semi-automation can shape the future of safety in ports while increasing economic and environmental performance.

Port Automation & Development

Container port automation is no longer just a technological goal but a strategic imperative for today's global logistics. Increasing trade volumes, growing labour shortages, and stricter environmental regulations are raising the demands on terminals to ever higher levels.

Automation offers a transformative solution - streamlining operations, improving safety, and supporting sustainability. It doesn't simply replace people but promises to upgrade roles and redefine port work in a way reminiscent of the great industrial revolutions of history. Find out why now is the time to move into the future of port operations.

Port Automation & Container Chassis

In this article, we discuss how container terminals in North America utilize chassis for moving and temporarily storing containers and how transitioning from analogue to digital yard management solutions can improve operational efficiency by up to 50%. Chassis-based operations, though prevalent and advantageous, often rely on labour-intensive manual processes. By adopting digital yard management systems equipped with real-time data inputs from chassis, terminals can significantly reduce container handling times, enhance productivity, and overcome the limitations of traditional methods.

Port Automation: Planning day-to-day

Container terminals form a vital gateway in the transport chain for the shipment of cargo containers. To handle the enormous amount of throughput, the advancement of information technology has played a crucial role in automating processes and transferring data seamlessly between the shipping lines and the terminal operators.

The essential objective for a container terminal is to shorten the vessel port stay as the vessels are most profitable while at sea.

Known Port Automation Challenges

The future of port automation is bright but challenging. Careful planning and implementation are necessary, based on proper process understanding, industry-wide standards, and the flexibility to adapt processes to customer demands. But what are the challenges to become an automated port?

Automation is an excellent recipe for improving the productivity of brownfield and greenfield container terminals. It is fair to say that semi-automation may hold some advantages against a full automated port in most scenarios. Operational flexibility is needed as you want to keep your processes open to changing customer demands.

Port Automation and Operational Safety

Even the most experienced safety professionals are not immune to risk—especially when routine checks become mere formalities. But, pre-operational safety checks (POSC) are not just boxes to tick; they are essential measures to keep people safe at the port and a strategic asset.

A well-executed POSC can make the difference between smooth operations and catastrophic failure in high-risk environments like container terminals. Discover why complacency, human error, and outdated processes continue to undermine safety—and how digital transformation is reshaping risk prevention.

VW Autostadt Infographic

The Autostadt in Wolfsburg focuses on all aspects of mobility. The theme park and educational centre is one of the most popular tourist destinations in Germany. The Autostadt is also the world's largest new car delivery centre and home to the multi-brand ZeitHaus car museum.

The Challenges of Port Automation

Container port automation is the application of automated systems to manage the movement of containers within a port or terminal. By design, it improves efficiency and productivity by reducing the time and cost associated with manual handling processes.

After a brief introduction to the shipping industry's history of automation, this whitepaper discusses the potential benefits for container terminals, looks deeper into port processes and uncovers the potential of automation before showing real effects on ports based on use cases rather than models.

PT TERMINAL PETIKEMAS SURABAYA

In 2015 Identec Solutions won their first Terminal Tracker project in Indonesia, which marked the beginning of a longstanding relationship with PT Terminal Petikemas Surabaya (TPS) and local integrator PT Primus.

The main objective of the solution is to perform Position Detection (PDS) and reporting moves performed by the Container Handling Equipment directly to the terminal operating system (TOS). The port automation solution removes the need for human interaction with the onboard display by automatically completing moves and ensuring an up to date and accurate yard inventory. This not only allows TPS to work more efficiently but also minimizes the risk associated with people working in the yard while delivering full visibility of the Terminals inventory.

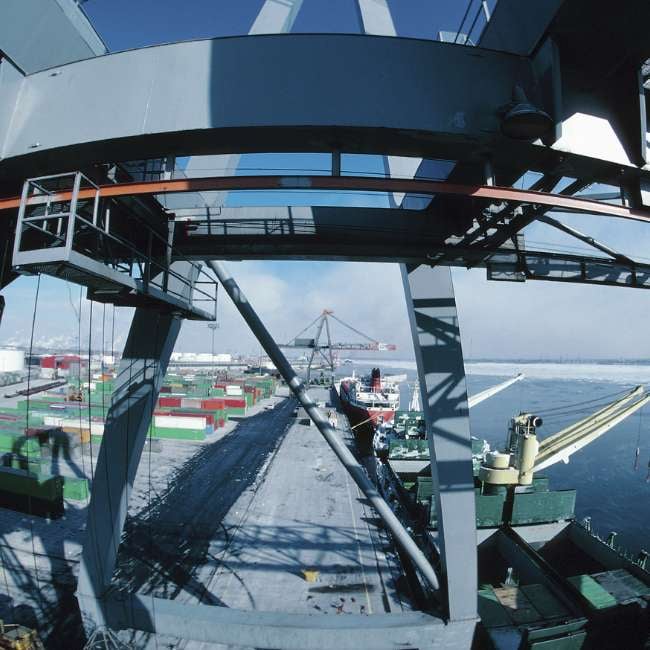

Port Automation in Montreal

Identec Solutions, a global leader in wireless sensor and localization technologies, partners with Visy Oy and Remprex on a groundbreaking project - Project Mercury - a C$11M initiative to revolutionize container data capture and tracking at Montreal Gateway Terminals Partnership's (MGTP) two largest terminals, Cast and Racine. The innovative port automation project leverages AI and OCR technology and the Identec Solutions' Terminal Tracker, aiming to overhaul manual operations, reduce greenhouse gas emissions, and enhance operational efficiency. Full-scale deployment is expected by Q2 2024, marking a significant stride towards automation and sustainability in the logistics industry.

Port Automation in Guayaquil

Contecon Guayaquil S.A. (CGSA) successfully integrated Terminal Tracker as part of its port development program to revolutionise its yard operation visibility and planning efficiency.

This strategic move within its port development visions has empowered the planning team at CGSA with unparalleled visibility and real-time awareness of yard activities. The project was carried out in phases. As it does not interfere with day-to-day usage and machine operation, it started with a single Rubber-Tyred Gantry (RTG) crane. Terminal Tracker demonstrated from the beginning the promised capability to deliver accurate stow positions, container weights, and other vital information to the Terminal Operating System (TOS). CGSA embarked on a full-scale implementation across its RTG fleet after a successful first phase.

TTI Algeciras

In 2020, TTI Algeciras was named one of the Top10 performing container terminals worldwide. This success story describes the motives, the project and the insights of implementing a core element to enable semi-automated terminal processes.