Cold Chain Logistics and Reefer Management

Cold Chain explained

The cold chain is one main artery of the global, intermodal supply chain. Its impact on national economies is significant, making regional products available worldwide. The cold chain covers all steps of temperature-sensitive goods between production or harvesting and retail: storing, packaging and shipping.

Chapter 1 gives you an overview of the dimensions, the importance and the parts of the global and regional cold chain.

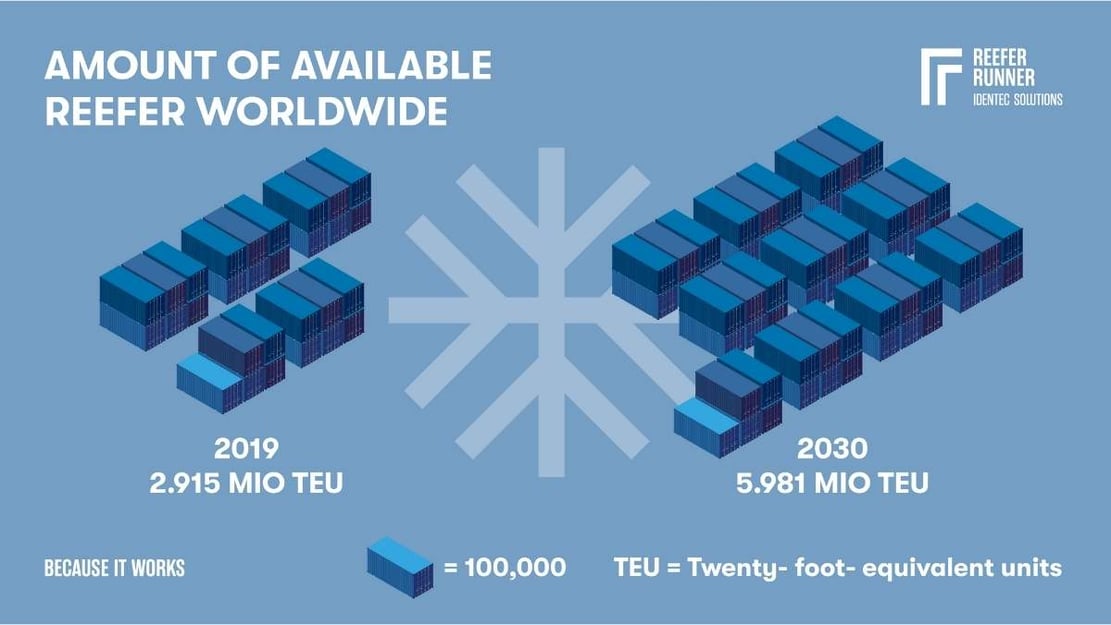

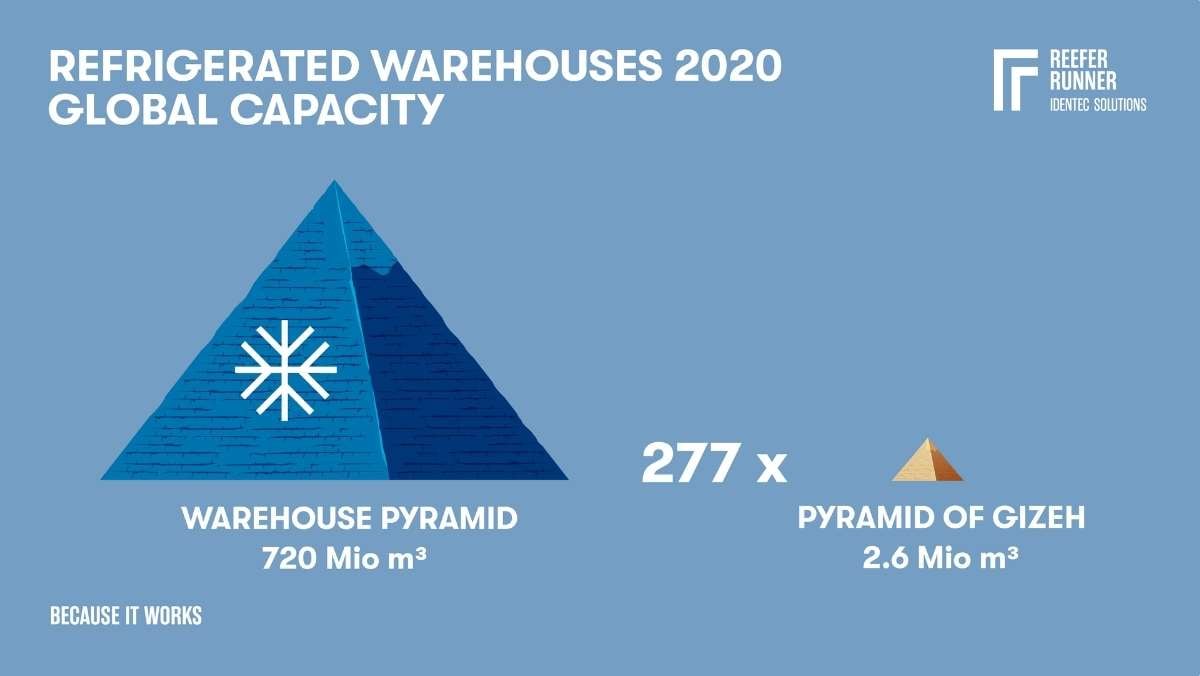

The world-wide dimensions of the cold chain

Cold chain logistics involves the transportation of temperature-sensitive products along a supply chain using refrigerated packaging solutions from harvesting and producing to the hands of the end-consumer. The goal is to preserve the quality of products such as fresh agricultural goods, seafood, frozen food and pharmaceutical products.

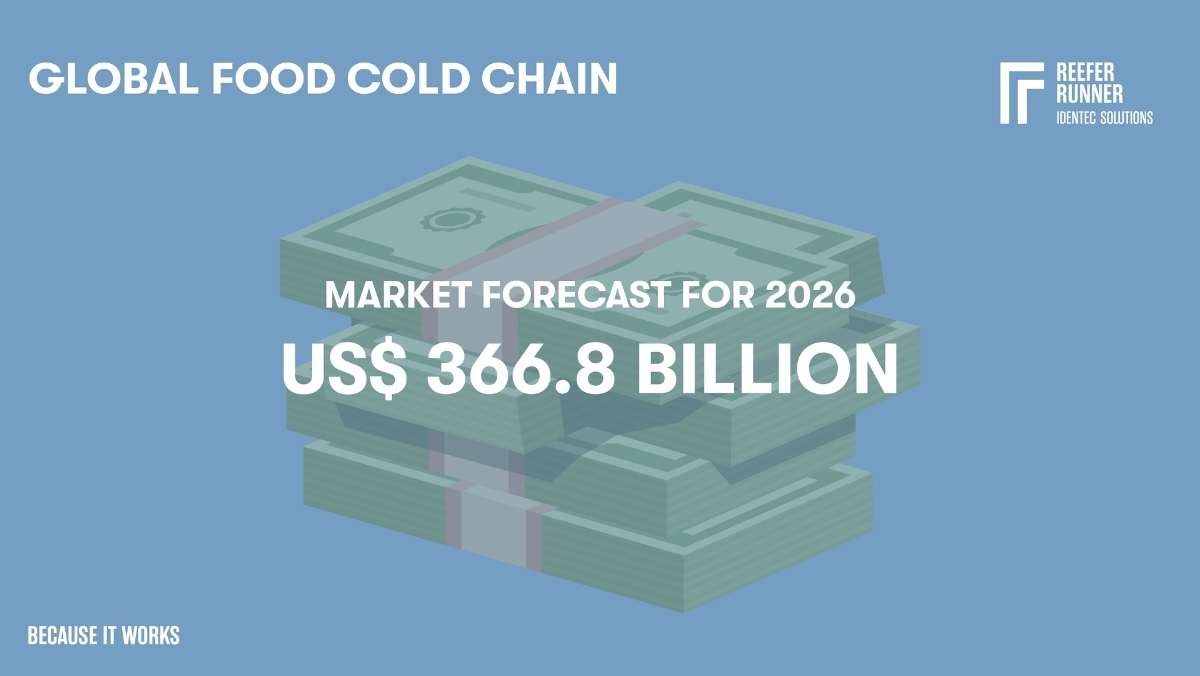

In 2020, the global cold chain logistics market was worth almost 248.4 billion U.S. dollars. It is expected to exceed 410 billion U.S. dollars by 2028.

The forecasted growth to 2030 is 15,1% per year, with the rising consumer demand for perishables and processed food products being the main driver for this sustained growth period. The largest cold chain market in 2021 was North America (37%).

Emission of greenhouse gases from refrigeration units, CO2 production by diesel gensets and food waste restrain the market growth. Consequently, industry continues to look for both economic and environmental solutions.

The European cold chain logistics market was worth over 75 billion U.S. dollars in 2019 and is expected to reach 112.8 billion U.S. dollars by 2025.

New Zealand as an example: significance of cold chain for a national economy

Due to its geographic isolation, New Zealand industries and exporters have been forced to experiment and innovate, with the result that many technologies and practices developed in New Zealand have been pioneering. At the beginning of the 20th century, most effort tended to focus around improving reliability and energy efficiency in meat refrigeration.

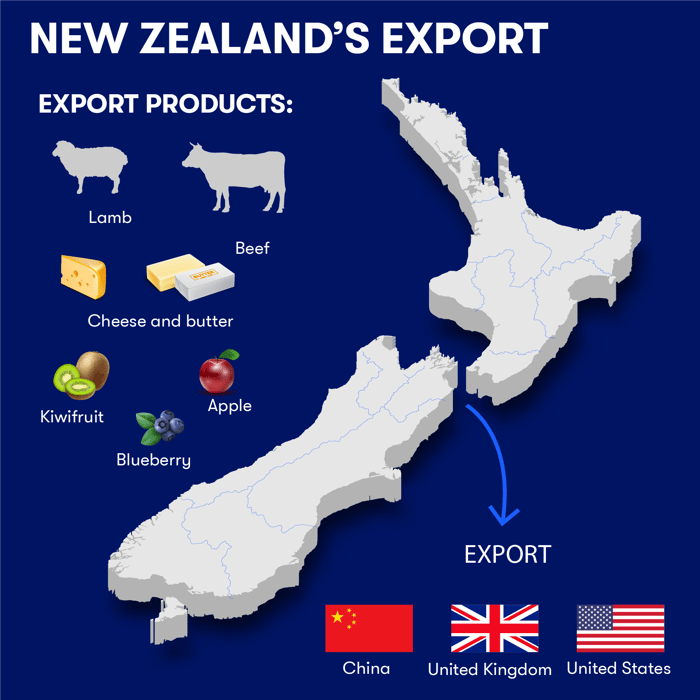

Today, approximately 45% of all exports from New Zealand are food products or by-products, and an estimated 60% of these are exported in the refrigerated state. The leading food sectors in terms of volume and income are the dairy industry, the red meat industry, the horticultural industry and the seafood industry.

New Zealand food exports form part of some of the longest cold chains in the world. Responsibility for temperature integrity in the cold chain is placed on the processors and exporters and is overseen by the Ministry for Primary Industry of the Government of New Zealand. Currently, the major research theme related to the cold-chain in New Zealand is focussed on optimising chilling and freezing processes for shelf-life extension.

Beef and lamb products dominate the red meat exports, with the United States, the United Kingdom and China being the three largest export markets. Most of the meat is exported frozen, but approximately 5% of beef and 15-20% of lamb products are exported chilled.

Cheese and butter are the major dairy exports that require refrigeration (although milk powder is the largest dairy export product by volume). Butter is commonly stored frozen to reduce the rate of lipid oxidation that causes spoilage.

The New Zealand fruit industry, with the exception of unrefrigerated wine, is dominated by the export of whole fresh product. Kiwifruit, apple, and avocado represent the bulk of the products while other export markets such as blueberry and cherry are emerging.

Due to the relative low volumetric efficiency (kg/m3) of packing that is a constraint of fresh produce, the volume of maritime cool-chain equipment used is substantial. In 2016, 68 chartered, refrigerated ships and a further 10,500 refrigerated containers where required to export New Zealand kiwifruit to 58 countries.

Due to the success of New Zealands export activity, but also from the rise in online grocery and food delivery volumes, mirroring international trends, cold storage-related property has been identified as one of the leading growth sectors in the industrial property market. The secure and safe storage of COVID-19 vaccines is also contributing to ongoing high demand in the cold storage sector in New Zealand.

The broader cold chain – including refrigerated containers, blast freezers and chillers, cold rooms, dedicated cold storage warehouses and refrigerated transport – is vital to New Zealand’s economy which is founded on the primary sector.

Because of the downstream effect of pandemic-restricted trade and disrupted supply chain movements throughout 2020, cold storage became somehow scarce and prices for cold storage space in New Zealand increased. Due to the specialised nature of the sector, developing purpose-built cold storage facilities requires deep pockets – particularly as energy-efficiencies are sought – and the ongoing maintenance costs over a facility’s lifespan are also significant.

Supermarkets are investing heavily to create more resilient supply chains and ramping up their ecommerce capabilities to reduce travel and delivery times.

Main elements of the cold chain

Talking about the cold chain as a process, there are certain elements that define this complex process. We can group them as:

- Cooling systems: Generating the appropriate temperature for processing, storage, and transportation. These can be stationary or mobile devices with or without their own power source.

- Cold storage: Providing storage of goods over a period of time (for instance, to be shipped or distributed). These can be stationary or mobile space / containers with or without their own power source.

- Cold transport: Using means of transportation available to move goods while maintaining stable temperature and humidity conditions to protect their integrity. Independently of the mode of transport, the cold chain must not be interrupted.

- Cold processing and distribution: Providing facilities for the transformation and processing of goods and ensuring sanitary conditions.

Four elements play a role within the cold chain and are necessary to deliver a product safely from A to B. The cold chain enables regional suppliers satisfiying global demand, but also distributing perishable goods to local consumers in a timely manner.

Transnational supply chains needs very often need a combination of transport modes making the 40-foot standard reefer container a must in intermodal transfers. Otherwise, unloading temperature sensitive cargo from one vehicle to another would break the cold chain and endanger the shipment.

Additionally, a cold chain container controls the environment electronically and maintain the set temperature for the entire duration of shipment.

The cold chain journey in a nutshell

Cold chain is a logistics management process for goods that require controlled temperatures during transportation and storage. It involves following processes to prepare, store, and transport goods along the supply chain. Failure to refrigerate cold chain products may render them unusable, leading to wastage. When goods requiring refrigeration are rendered unusable, both the shipper and their client (owner of the goods) can lose money, and supply decreases for end users (read also: Container damage claim and the Cold Chain)

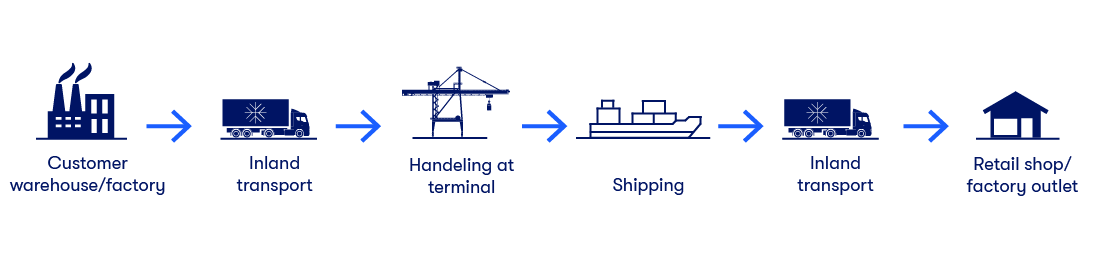

Overall, the cold chain consists of the following steps:

- Make the good transport-ready at the customer farm, warehouse or factory

- Prepare the transport and manage transportation booking

- Conduct inland transport and, if necessary, clear customs

- Temporarily store goods at terminal and load them on the vessel

- Ship containers across the sea

- Unload, store goods at terminal and clear customs

- Forward goods via inland transport

- Store goods in a cold storage or warehouse for last mile

- Distribute to retail shops or factory outlets

From Farm to Cold Storage

Before temperature-sensitive goods can be shipped, they must be prepared for transport. Most importantly, pre-cooling to the desired temperature must be done before long-distance shipping. As every product has different optimal temperature zones, humidity and air composition when stored, the transport set-up of reefer shipments is individual.

Chapter 2 introduces you to the concept and technologies of cooling and freezing of temperature-sensitive goods.

Pre-trip preparing

Proper cold chain (also: chill chain) logistics include planning and implementation of the safe and secure transportation of temperature-sensitive products over long distances. Temperature-sensitive products include certain types of food and beverage items, pharmaceutical drugs and biological samples and specimens to name a few.

The term ‘cold chain logistics’ can be a misnomer at times. Depending on the type of product, the temperature requirements to store and transport it will vary. Not every product has to be kept at low or sub-zero temperatures, some products may need storage and transport at ambient temperatures to preserve texture and quality. This is true especially during harsh winters in certain regions.

Moving a shipment across the supply chain without suffering any cold chain break requires the establishment of a comprehensive logistical process. This process concerns several phases ranging from the preparation of the shipments to final verification of the integrity of the shipment at the delivery point.

The journey of temperature-sensitive goods starts with the producer. Whether farmer or manufacturer, to maintain the quality of sensitive cargo during shipment, they must be packaged correctly. Proper packaging helps minimise risk of product contamination but also ensure energy-efficient storage of products along the cold chain.

Immediately after post-production, goods must store adequately until they are dispatched to a distribution point. These storages must hold goods in temperature-controlled conditions protected from temperature fluctuations and power outages. Such outages can result in damage or spoiled goods. Therefore, most temperature-controlled warehouses have the back up of an Uninterruptible Power Supply (UPS) to meet such unforeseen dangers. Infrared thermometers or other sensors help to record the temperature.

If manufacturers of temperature-sensitive products don’t have storage equipment needed to keep their products cold, they’ll have to outsource their cold chain operations to a partner who can provide the necessary equipment. Some common types of cold storage equipment and facilities include refrigerated containers, cold rooms, chillers, cold boxes, and also vaccine carriers.

When preparing products for a refrigerated shipment, consider the following:

- Cargo should be pre-cooled to the required temperature before being moved into the reefer container.

- Additional setting requirements such as dehumidification control, fresh air ventilation and controlled / modified atmosphere, if necessary.

- Maximum shelf life and transport time to plan ahead.

- Required documentation, legal restrictions and other rules and regulations for customs and legal authorities.

- Volume and weight of the goods for documentation and respecting safety limits.

- General stowage instructions.

- Optimum packaging material and cartons for perishable cargo.

How to control temperature

Maintaining the correct temperature is a key aspect of a cold chain. Imagine your perishable goods at home – your refrigerator is your chilled warehouse to keep temperature-sensitive goods safe for a specific duration. It offers different areas to store goods– vegetables, cheese, beverage and frozen goods are not in the same compartment. On a larger scale, industry constantly improved technology and processes over decades to provide reliable temperature controlled environments.

As different products require different temperature levels, the logistics industry has come up with an array of cooling methods. They depend on the type of cargo, the duration of transit, the size of shipment and the outside temperature. Solutions range from small insulated boxes to a containerized refrigerator unit.

The primary cold chain technologies in providing a temperature-controlled environment during transport include:

- Dry ice: Solid carbon dioxide is about -80°C and can keep a shipment frozen for an extended time. It is mainly used to ship pharmaceuticals, dangerous goods, perishable food, and refrigerated unit load devices for air cargo. Dry ice does not melt. Instead, it sublimates when it comes in contact with air.

- Gel packs: Gel packs are widespread in sports as they provide cooling when needed without leaking water. In logistics, they have a similar use as large percentages of pharmaceutical and medicinal shipments are classified as chilled products (to be stored in a temperature range between 2 and 8°C). The standard method to provide this temperature is to use gel packs or packages that can go from solid to liquid and vice versa to control an environment. These packs can start in a frozen or refrigerated state, depending on the shipping requirements. Along the transit process, they melt into liquids while at the same time capturing escaping energy and maintaining an internal temperature.

- Eutectic plates: They are also known as “cold plates”. The principle is similar to gel packs. Instead, plates are filled with a liquid and can be reused many times. Eutectic plates have many applications, such as maintaining cold temperatures for rolling refrigerated units. They keep the temperature in delivery vehicles stable for a short time. This is suitable for deliveries in noise-sensitive areas or night deliveries.

- Liquid nitrogen: An extremely cold substance, of about -196°C, is used to keep boxes frozen over a long time and is mainly used to transport biological cargo such as tissues and organs. It is considered a hazardous substance for transportation.

- Quilts: Insulated pieces are placed over or around freight to act as a buffer in temperature variations and maintain a constant temperature. Thus, frozen cargo will remain frozen for a more extended time, often long enough not to justify the usage of more expensive refrigeration devices. Quilts can also keep temperature-sensitive freight at room temperature, while outside conditions can substantially vary (e.g. during the summer or the winter).

- Reefers: Temperature-controlled transport units like a van, small truck, a semi-trailer, or a standard ISO container are called reefers. These units, which are insulated, are specially designed to allow temperature-controlled air circulation maintained by an attached and independent refrigeration plant. Therefore, a reefer can keep the cargo temperature cool and even warm. The term reefer increasingly applies to refrigerated forty-foot ISO containers, with the dominant size being 40 high-cube footers (45R1 being the size and type code).

- The cold storage facility: It is the most typically used in cold chain logistics. It can vary from a single temperature-controlled room servicing a single user and function to a large, dedicated distribution centre servicing multiple users and roles. There are also singular examples, such as converting mines into cold storage facilities.

Collecting and loading shipment

When preparing temperature sensitive cargo, pre-cooling, packaging, and stowage are essential aspects. It is the first step to maintain the shipment integrity.

Step1: Pre-cooling

As mentioned above, pre-cooling of cargo is important for the following reasons:

- Proper pre-cooling of product is essential, because it rapidly removes heat from commodities before shipping, storage, and processing.

- Proper product pre-cooling reduces the rate of water loss and spoilage for many perishables and helps maintain freshness and quality.

- Remember: Reefer containers are built to maintain product temperatures, not to reduce their temperature.

But not only cargo must be pre-cooled, also refrigerated containers need pre-cooling:

- Transferring a cold product to a warm container can result in surface thawing and freezer burn. When necessary, the container should be pre-cooled to the appropriate carriage temperature before loading. Frozen products should be loaded rapidly, especially in warm weather when ambient temperature may be high.

- Pre-cooling of the reefer container is required only when a proper loading bay (i.e., with ‘cold tunnel’ loading facilities) is available and the temperature in the cold store and in the container is identical.

- Proper loading facilities consist of a tight insulated duct between the cold store and container to prevent warm, highly humid, ambient air from entering the reefer container.

Step 2: Packaging

Packaging must be properly designed, constructed, and stowed to protect the product.

- Stacking strength: Cartons must be designed to withstand the weight of other stacked cartons. Overloading cartons and stacking them beyond their designed limits can cause damage to the cartons and their contents.

- Protection from moisture loss: Most packages must be able to tolerate exposure to high relative-humidity levels during transportation and marketing.

- Aiding temperature management: Appropriate vent cartons for chilled cargo promote proper airflow through the container. Cartons should be vented on the top and the bottom to allow air to circulate upwards through the load

- Protection from rough handling: Packaging must be able to withstand a variety of handling and environmental conditions. Improperly designed cartons are more susceptible to collapse under rough handling and high humidity conditions.

Step 3: Storage

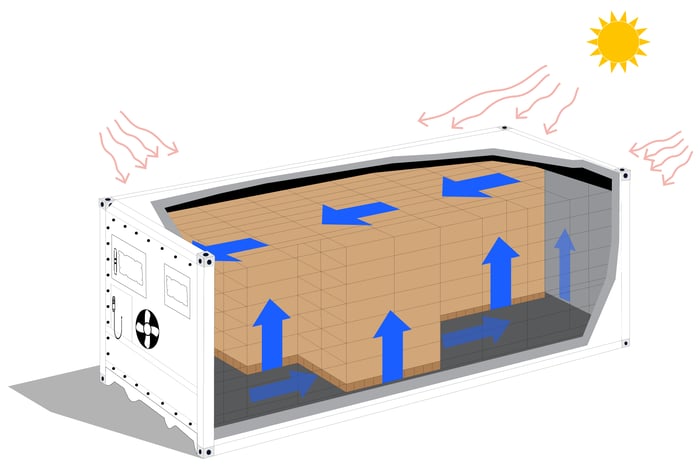

Proper stowing is essential to enable airflow for desired temperatures. Post-harvest life can be stretched out having a stowage plan and an understanding how stowage patterns affect airflow through the reefer container. It is important to cover the entire floor with pallets, boxes, or other materials, and do not load above the red line.

Because chilled cargo (such as fruits and vegetables) generate heat during respiration, it is essential to ensure that circulating air can pass through (and not just around) the stow providing aeration for the load. Additionally, chilled produce needs to be block stowed or stacked as a solid block to facilitate the reefer container’s bottom air (vertical flow) delivery passing through the cargo.

Air vents along the boxes are optional. It is also recommended to use a refrigerated container equipped with cargo tie-down rings and restraining devices.

It is necessary to ensure air can float under, over and to each side and end of the cargo. When stowing produce in containers with flat-sided walls, slightly loose stowage is necessary for air circulation to allow refrigerated air to circulate evenly around the cargo and ensure that any heat penetrating the container does not encounter the load.

The right temperature for temperature-sensitive cargo

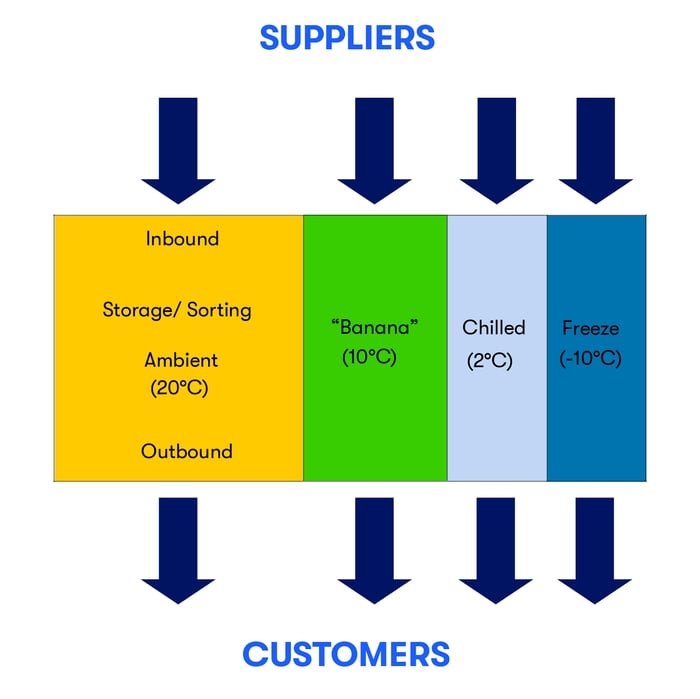

Cold chain goods are often stored in refrigerated warehouses until shipment order has been given. Specialized distribution centres are designed in such a way that they can meet essential requirements to house the goods before delivery to the customer. The entire system of temperature-sensitive goods distribution must fulfil demand in a timely fashion, primarily for the distribution of perishable food products.

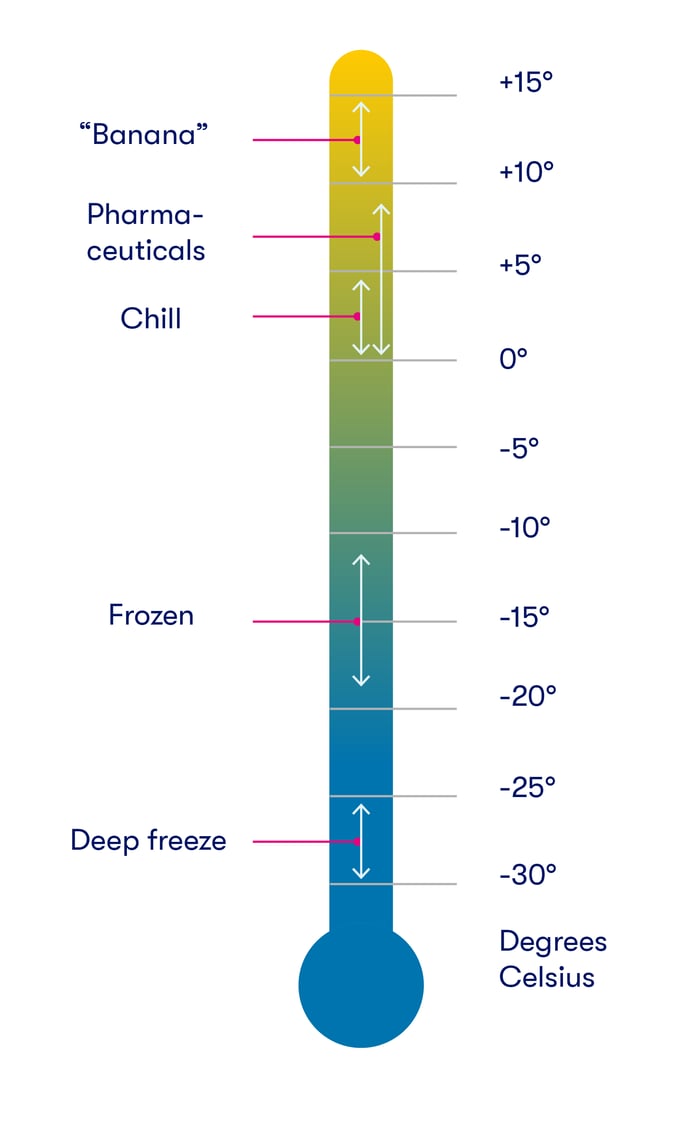

Cold chain logistics provides producers as customers with the facility for temperature-controlled warehouses and transportation. There exist five standard temperature settings for specific product types:

- Deep freeze (−25 to 30 °C): This temperature range is the coldest. A conventional type of refrigerator is used for the transportation of goods like ice-cream and seafood.

- Frozen (−10 to −20 °C): This temperature range is for products like frozen meat, beef, poultry, pork, and frozen bakery products.

- Chill (2–4 °C): This temperature range is the standard range commonly used to store food products like vegetables, fruits, and fresh meat, but also cut flowers.

- Pharmaceuticals (2–8 °C): Most vaccines are transported in this temperature range. However, these products are usually being transported in reefers, but for small packages also in vans.

- Banana (12–14 °C): This temperature range is the most common range used for the shipping purpose of oranges, pineapples, and vegetables like potatoes.

Learn more about the supply chain of pharmaceuticals here...

Wine is also temperature-sensitive. The hotter you stow wine, the quicker it will age. The more it ages, the flatter the taste. If your wine takes several days to ship, you must ensure it can tolerate fluctuating temperatures and still arrive at an optimal quality.

Medical products are temperature-sensitive. High or sub-zero temperatures can impact the chemical stability of the medicine, and may even change its physical properties causing sedimentation and separation of emulsion systems.

Therefore, protect vaccines, blood, insulin, medical devices, blood products like plasma or other pharmaceutical products from heat and cold. Depending on the product, certain medical products must be kept at near room temperature (between 18-23 °C or 64- 73 °F). On the contrary, live vaccines must be held at 5°C (within the 2-8 °C range) or lower; otherwise, they will degrade.

Due to the implications of improperly stored drugs, regulator requests have become more stringent, and pharmaceutical companies need to be able to prove that their products are transported via a temperature-controlled supply chain.

Not all products listed above get spoilt as soon as the temperature crosses the thresholds shown. It is more problematic when the temperature fluctuations are steep and frequent, causing them to spoil.

HOW TO PREPARE FROZEN CARGO FOR SHIPMENT

The key factors affecting the shipment of frozen cargo include:

- Pre-cooling: Appropriate pre-cooling of containers for the shipment of frozen cargo helps to prevent: any type of surface thawing, freezer burn and condensation.

- Freezing process: As a rule of thumb, fast freezing leads to superior product quality, but slow freezing ends up in the formation of large ice crystals that destroy cell walls and result in soft, mushy products. Therefore, food should be solidly or almost solidly frozen as an unfrozen core will lead to damages in texture, colour, flavour and other properties. This is because the effective freezing process inhibits micro-organisms and slows most enzyme activities and oxidative processes.

- Thawing: The most damaging process to frozen products is the repeated freezing and thawing. Proper temperature management is therefore crucial because temperature fluctuations that cause thawing can be damaging.

- Packaging: Proper packaging and glazing can protect most foods from freezer burn (surface drying that produces unsightly appearance and nutrient loss), bacterial contamination and the effect of oxygen. Packaging material should not only be impermeable to water vapor and oxygen, but also to volatile odours and substances.

- Stowing: Frozen cargo should always be stacked as a solid block, to allow air to circulate around the periphery of the load (see above).

- Ventilation: The fresh air vent must always be closed tight and sealed for all frozen cargo shipments.

How to keep chilled cargo fresh

Chilled cargo needs to be shipped above product freezing temperatures. Such commodities are more sensitive than others due to characteristics and varying factors affecting their shelf lives. Due to relatively short shelf lives, this type of cargo requires careful attention during transportation. It is necessary that reefer containers use the supply air sensor to detect and manage temperatures within a 0.5°C (0.9°F) range or better, and automatically control refrigeration.

A key component of chilled cargo are horticultural commodities. Horticultural commodities continue to “live” after harvesting, and refrigeration is crucial to ensure that the product retains its commercial value from harvest to its destination. The key factors contributing to the shelf life of horticultural commodities are:

Respiration

Fruits and vegetables continue to breathe after harvest, generating heat, consuming oxygen, and giving off gases such as carbon dioxide and moisture. This respiration process influences the commodity’s value, flavour, quality, colour, texture, and water content and may degrade their value. In addition, fruits and vegetables have different respiration rates, which is part of the natural ripening process. For example, commodities such as potatoes and onions have low respiration rates and enter a dormant state when harvested.

Other vegetables such as broccoli and asparagus, which are harvested during an active phase of growth, have relatively high respiration rates, as do products with short post-harvest lifespans.

Temperature

Temperature is the most important factor in preserving the quality of harvested products. The respiration rate is directly proportionate to the rate of deterioration, which increases exponentially as temperatures increase. As a rule of thumb, for every 10°C (18°F) increase in temperature, the rate of deterioration increases two to three times over.

Maintaining the desired temperature range during transportation will maximize shelf life and quality:

- Lowering respiration rate.

- Reducing moisture loss and wilting.

- Avoiding spoilage due to bacteria, fungi, and yeast.

- Slowing down undesirable growth such as sprouting.

It is essential to avoid any variations of temperature. Too high or low temperatures will lead to undesirable outcomes, especially when the temperature is constantly fluctuating.

When organic products are exposed to high temperatures, it will have unintented effects:

- Losing water at a faster rate.

- Producing ethylene.

- Enabling conditions for disease-forming organisms.

- Changing the physiological state of the product.

- Accelerating uneven ripening, surface scalding and decay.

When organic products are exposed to low temperatures, it will affect goods also:

- Sustaining chilling or freezing injury.

- Experiencing surface pitting and watery areas.

- Losing colour.

Ethylene production

Ethylene gas is a natural by-product of perishables during respiration. It can be used to control the ripening process if managed properly. Commodities react differently to ethylene levels and concentration, which play a vital role in the freshness of the goods. Temperature, oxygen, and carbon dioxide levels are other factors besides ethylene which are critical to the ripening of perishables. Some commodities are very sensitive and react at ethylene concentrations as low as 0.1ppm (parts per million) when exposed over long periods of time.

The key factors affecting the rate of ethylene production in the commodity include:

- Temperature

- Maturity

- Physical injury (e.g. pressure marks)

- Environmental pollutants

Water loss

In horticultural crops, water loss after harvest has a direct impact on their life cycle and is a major cause of deterioration. Perishables retain their market value and are deemed as of better-quality if water is not lost during shipment. Greater water loss will generally be experienced by:

- Leafy vegetables with larger exposed surface areas (in comparison with fruit).

- Plants that have been bruised or cut (in comparison with undamaged plants)

Water loss can be minimized by ensuring:

- Lowest safe temperature

- High humidity of 85% - 95%

- Rapid pre-cooling

- Appropriate packaging

Respiration rates

Respiration rates of selected commodities

| Very low | Dates, dried fruit, nuts |

| Low | Apples, citrus, garlic, grapes, kiwi, onions, potatoes (mature), sweet potatoes |

| Moderate | Apricots, citrus, garlic, grapes, carrots, cherries, figs, lettuce, mangoes, nectarines, peaches, pears, peppers, plums, potatoes (immature), tomatoes |

| High | Avocados, blackberries, cauliflower, lima beans, rasberries, strawberries |

| Very high | Artishokes, brussel sprouts, cut flowers, green onions, snap beans |

| Extremely high | Aspargus, broccoli, mushrooms, peas, spinach, sweet corn |

Ethylene PRODUCTION rates

Respiration rates of selected commodities

| Very low | Artichokes, aspargus, cauliflower, cherries, citrus, grapes, jujubes, leafy vegetables, most cut flowers, pomegranates, potatoes, root vegetables, strawberries, watermelones |

| Low | Blueberries, cranberries, cucumbers, eggplant, okra, olives, peppers, persimmons, pinapples, pumpkins, raspberries, tamarillos |

| Moderately high | Apples, apricots, avocados, bananas, nectarines, papayas, peaches, pears, plums, tomatoes |

| Very high | Cherimoyas, passion fruit, sapota |

Inland transportation

Controlling temperature during transport, proper loading and stowing of the shipment and monitoring airflow and humidity are critical to guarantee unspoiled goods when arriving at the destination. Reefer container takes charge of the controlled environment of cargo, independently of the transportation mode.

Chapter 3 dives into reefer container technology and supply chain integrity on rivers, tracks and roads.

Cargo treatment during transport

The quality and freshness of temperature-sensitive products can alter with even the slightest changes in temperature, making it very important to regulate temperature and keep these items safe during transport. When goods are transported from one point to another, it has to be done in temperature-controlled vehicles that are equipped with refrigeration devices to meet the requirements of the goods. Alternatively, high-performance insulation may keep the desired temperature stable for a short time.

By 1938, Frederick McKinley Jones invented the first-ever portable air-cooling units for use on trucks. This was a huge step for food-safety. He built a multi-million-dollar company by 1949, which included the introduction of the first ever fully refrigerated truck. These temperature-controlled vehicles are also known as reefer trucks: a standard semi-cab pulling a refrigerated trailer.

These trailers differ from cooling vans, which are just insulated and vented. What makes a reefer trailer different? Reefers include an active cooling system. Thus, you can transport frozen as well as refrigerated freight. Such trucks have a separate compartment or container that is temperature-controlled using portable refrigeration units.

The refrigeration units run on diesel or battery power. Reefers usually have electronic temperature monitoring and logging devices that record and report temperatures and other conditions such as humidity inside the reefer. They monitor from the moment the devices are switched on after loading of goods, until the goods are offloaded at their destination.

These devices, known as Electronic Data Logging Monitors (EDLM), are compact and portable devices that record environemntal parameters at defined intervals. They may even be programmed to send alarms to the operator under certain conditions.

Some of them have alarm systems that trigger when the reefer door is opened or when the temperature goes below or above a set threshold. Some of them are satellite-linked for remote monitoring.

Passive data loggers are also used that record the temperature at intervals.

These are typically portable measurement instruments that are capable of autonomously recording temperature over a defined period of time. The digital data can be retrieved, viewed and analysed. A data logger is commonly used to monitor shipments in a cold chain and to gather temperature data from diverse field conditions. This recorded data can then be downloaded and studied at a later point in time.

Another method of maintaining low temperatures inside a transport vehicle with a separate storage compartment is by using dry ice or frozen gel packs. This method known as the passive system of cooling is used for short-distance transport of products that need storage in cool environments.

Selection of the right kind of containers for packing temperature-sensitive products, tracking temperature, humidity, and such conditions during handling and transport, and avoiding temperature fluctuations is the key to managing cold chains effectively.

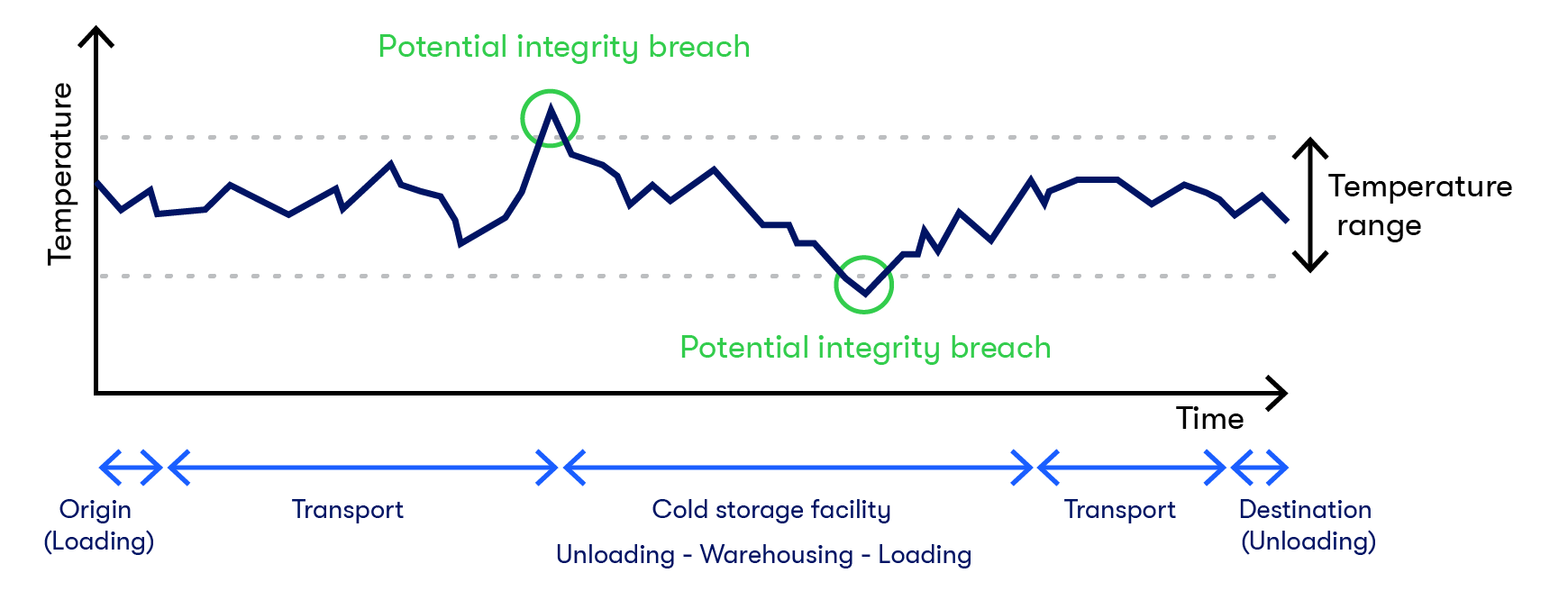

Cold chain integrity

Monitoring of the supply chain is referred to as supply chain integrity. This working concept helps in identifying locations where possible breaches are taking place, often called the identification of liability. The crucial element of the cold chain, which offers a controlled transport and storage unit, are the reefers as mentioned above.

Reefers have two potential breaches which require monitoring. First, the reefer is not connected with the power source at the time of transhipment, or the reefer door has been kept open for an extended period. Second, it may happen that the product is being transported at a higher or lower temperature than is specified by the producer. As a result, there may exist a decline in the product’s shelf life. Due to the growth of shipments handled by temperature-controlled devices, attention must be given towards identifying the locations, types of equipment, and the circumstances in which a breach in the integrity can take place.

Reefer technology at a glance

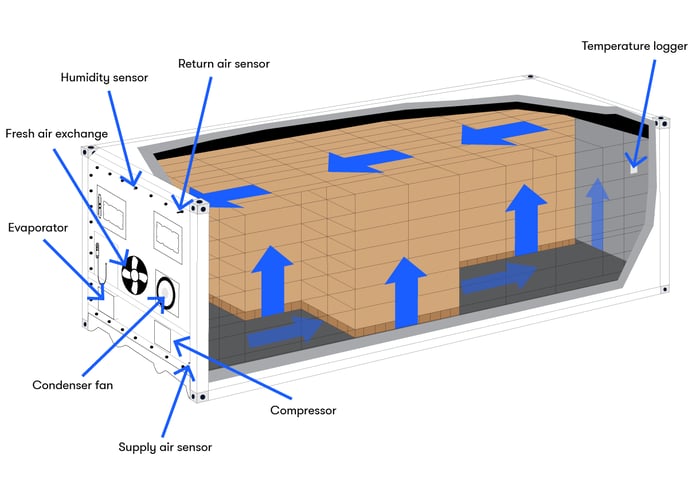

Components of a reefer refrigeration system

Reefer units operate on a closed system. Removing heat and maintaining a steady temperature is what a refrigerated trailer system is all about. They operate by collecting and pumping heat throughout the system and manage product temperature. Most refrigeration units have excess cooling capacity to maintain product temperatures.

The refrigeration unit consists of the following:

- Compressor

- Condenser / fans

- Evaporator / fans

- Fresh air exchange

- Temperature controller

- Supply air sensors

- Return air sensors

- Humidity sensor

Power sources and portable generators

Refrigerated containers operate on external power sources. The power supply used is generally a 3-phase (industrial) voltage supply of 380 volts/50 Hz or 440 volts/60Hz. Containers may be plugged into a vessel’s main power supply at sea, a reefer plug in a container terminal or equipped with a power generator for land use (find out more about reefer plugs here).

Two types of portable generators are available:

- Underslung generator mounted beneath the chassis of a moving truck.

- Clip-on generator attached to the “nose” of a container on a moving train or truck.

A portable generator set or “genset” is required to continuously power the reefer container when it is disconnected from the power supply in a container terminal and loaded on a truck because cargo is vulnerable to the ambient temperature if left without cooling or heating for extended periods of time. Some gensets are capable of providing 15KW (18.75KVa) of continuous power output at ambient temperatures ranging from -40°C to +52°C (-40°F to +125°F) for long-haul transportation up to 7 days with a 125-gallon integrated fuel tank, subject to carriage temperature and ambient heat.

Refrigerated container types

Three different types of reefers are available for a reliable cold-chain today. Depending on efficiency, purpose, cargo and your requirements, one or the other can be used.

- Closed reefer: This is a conventional reefer that comes in a single piece. It has an integral front wall and all-electric automatic cooling and heating units.

- Modified Atmosphere/Controlled Atmosphere (MA/CA) reefers: These are insulated containers with an air exchange system that keeps the atmosphere constant by replacing the consumed oxygen. As such, the atmosphere in these containers is in equilibrium with the deterioration rate of the cargo.

- Automatic Fresh Air Management (AFAM) reefer: This container uses cutting-edge technology to automatically adjust air exchange within the container to maintain a constant temperature. Similar in its working to the MA/CA reefer, the AFAM reefer controls the composition of oxygen, carbon dioxide and other gases. Its controls can be adjusted to extend the shelf life of cargo, irrespective of outside conditions.

Reefer Container Dimensions

The size of the reefer containers can vary depending on the producer, but the standard sizes are:

20FT Reefer container

| Tare weight | Payload capacity | Cubic capacity | Internal length | Internal width | Internal height | Door opening width | Door opening height |

| 3,080 kg | 27,400 kg | 28.3 m³ | 5.44 m | 2.29 m | 2.27 m | 2.23 m | 2.10 m |

| 6,791.4 lbs | 60,417 lbs | 999 cu ft | 17.9 ft | 7.5 ft | 7.5 ft | 7.3 ft | 6.9 ft |

40FT Reefer container

| Tare weight | Payload capacity | Cubic capacity | Internal length | Internal width | Internal height | Door opening width | Door opening height |

| 4,800 kg | 27,700 kg | 59.3 m³ | 11.56 m | 2.28 m | 2.25 m | 2.29 m | 2.26 m |

| 10,584 lbs | 61,078.5 lbs | 2,093.3 cu ft | 38.0 ft | 7.5 ft | 7.4 ft | 7.5 ft | 7.4 ft |

40FT High cube Reefer container

| Tare weight | Payload capacity | Cubic capacity | Internal length | Internal width | Internal height | Door opening width | Door opening height |

| 4,480 kg | 29,520 kg | 67.3 m³ | 11.58 m | 2.29 m | 2.40 m | 2.29 m | 2.57 m |

| 9,880 lbs | 65,080 lbs | 2,380 cu ft | 38.0 ft | 7.5 ft | 7.9 ft | 7.5 ft | 8.4 ft |

45FT Reefer container

| Tare weight | Payload capacity | Cubic capacity | Internal length | Internal width | Internal height | Door opening width | Door opening height |

| 4,850 kg | 28,150 kg | 67 m³ | 11.57 m | 2.27 m | 2.55 m | 2.29 m | 2.26 m |

| 10,694.3 lbs | 64,275.8 lbs | 2,365.1cu ft | 38 ft | 7.4 ft | 8.4 ft | 7.5 ft | 7.4 ft |

Reefer container models and handling

Safety Precautions

Due to the system’s character, several safety precautions must be closely adhered to. While wearing personal protection equipment (PPE) like glasses and safety gloves, others may not be as common.

- Always keep your hands, clothing, and tools away from the fan when it‘s in motion.

- Always detach the power source before repairing.

- Use a CO2 extinguisher to put out flames if they occur.

- Follow the manufacturer’s recommendations when handling refrigerant containers.

- Always work in a well-ventilated area.

If there are any doubts about what needs to be done to repair or shut down a reefer’s refrigeration system, the best is to contact the manufacturer or a professional technician.

Possible Problems

Reefer containers can experience various issues that will affect the internal temperature of the refrigerated unit.

- Bad seals around openings will cause leakages allowing cool air to escape.

- Damaged pressure lines due to bending or regular wear and tear.

- Electrical malfunction.

- Weakened refrigerant that needs to be substituted after extended use.

Most of the problems that occur with reefer containers happen due to day to day use. Over time, seals can weaken, and refrigerant can lose its “coldness”. These are simple fixes that can be achieved by yourself, but it’s best to have a professional technician do the job in most cases.

Refrigerated containers are essential when transporting products and merchandise that require a specific environment to remain viable. Maintaining the heating/cooling unit and its power supply will allow you to get your container’s best use out of many years. If you have any questions, always refer to the manufacturer to have the most accurate information for your singular unit, especially if you are trying to make repairs. Refrigerated containers are now being operated using the most advanced forms of technology, making it easy to manage the system and protect your product/merchandise.

Reefers on the way: river, rail, road and air

Cold transport affects deploying different transport solutions to move temperature-sensitive products from the point of storage to the consumer market. Cold chain products can be ferried by road, rail, air, and/or sea. Various specialised transport vehicles and equipment, such as refrigerator vans, refrigerator trucks, and reefer containers, are used to transport and keep shipments cold.

Sometimes, the transport of goods may only require one transportation mode, but shipments often use a combination of transport modes. Intermodal transfers are vital for the cold chain, using typically 20 or 40-foot refrigerated containers. The container makes loading and unloading periods shorter and less sensitive to damage both on the container and its cargo.

River

Inland transportation by rivers offers some cost benefits against road and rail transport. Rivers are natural arteries that do not require any construction and maintenance costs. Even the cost of building and maintenance of canals is much less. Yes, it is slower and depends on the water depth, but it is maybe the most ecological solution of all inland transport ways. In addition, river barges are more and more used for containers and reefer transport from sea hubs to inland hubs along rivers. Vessels also avoid truck congestion at the ocean port and exceed road weight limits.

Moving goods on the water is the most efficient transportation way. For example, a typical inland barge has a capacity 15 times greater than one rail car and 60 times greater than one semi-trailer truck, and one 15 barge-tow can move the equivalent of 216 rail cars or 1,050 semi-trailer trucks.

Rail

Transportation of refrigerated containers by rail is a natural extension of sea transport and a link of multi-modal transport, although it is a pure inland service. Today’s rail transport of refrigerated containers is a common way of transporting perishable goods. If in the 1990s it was quite an exotic mode, today it promotes design and construction of particular platforms, development of terminals infrastructure and enhancement of the regulatory framework. Moreover, due to the extensive network of railways, reefer shipping becomes possible in vast areas.

Road

Reefer trucks and reefer trailers are used for refrigerated road transport. A reefer trailer is an insulated container with a refrigerating unit attached. Reefer vans are smaller vehicles for shorter transits than reefer trucks used for longer-range refrigerated transport. Some trucks even transport reefer containers. The refrigeration unit controls the container’s temperature and sits out on top of the cab or back of the trailer.

A compressor supplies the unit with power generated from the truck or container. The entire set-up consists of a generator, the compressor and the insulated box. Refrigerator trucks can also be ice-cooled or utilize carbon dioxide (dry ice or liquid) as a cooling agent.

Air

It is the fastest way to transport goods – also refrigerated ones. Many products like medicine were previously delivered by air. Although with technological improvements of reefer containers and the introduction of guidelines for maritime and inland waterway transport in several industries changed. As a result, operators handling valuable cargo have a great need for safety and insight.

Isothermal containers are the best choice to maintain the cold chain in air freight. Insulated packaging is essential but needs coolants to be sufficient on direct flights.

Coolants such as dry ice are carbon dioxide in solid form and evaporate over time. In air freight, it is considered a hazardous substance, which tends to increase freight charges and limits the types of planes it can be loaded onto.

All means of transport must ensure that the cold chain is not broken or interrupted. Following the location of the reefer and the conditions inside the reefer are essential to monitor, to record monitoring data and to intervene if necessary.

VW Autostadt Infographic

The Autostadt in Wolfsburg focuses on all aspects of mobility. The theme park and educational centre is one of the most popular tourist destinations in Germany. The Autostadt is also the world's largest new car delivery centre and home to the multi-brand ZeitHaus car museum.

Container terminal operations

Ports in general, and container terminals in particular, are the most important dots in the global supply chain. Handling refrigerated containers in terminals is critical as they wait to continue their journey to their destination. Providing power and monitoring the desired temperature and energy setup is vital.

Chapter 4 takes you to container terminals and their handling of reefer containers.

Handling reefers in ports

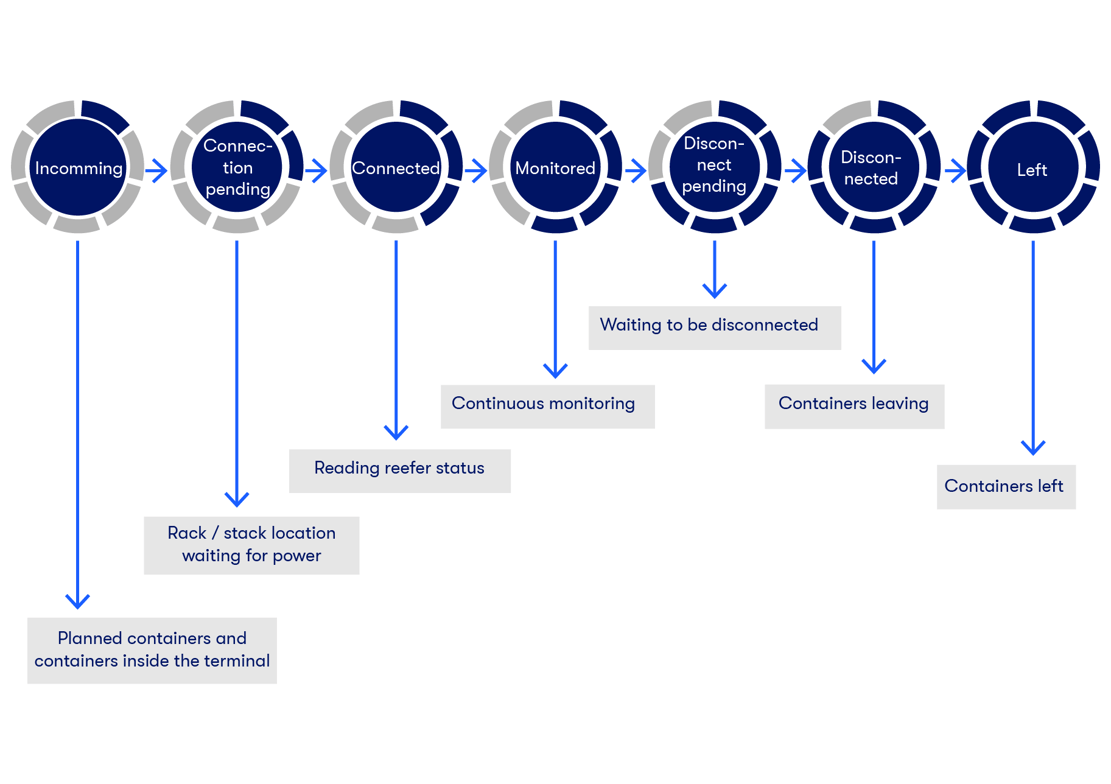

In cold chain logistics, ports play a central role on a global scale. They are the connecting dots between continents, seas and the hinterland. A container terminal offers substantial space for convenient refrigerant stores and yard space for refrigerated continers. Shore-based communal power supplies reefer racks, and each individual reefer can be monitored either manually or through a central platform. In this process, the temperature of the cargo is monitored to ensure it remains within the specified range.

If temperatures are not maintained, the operator is subjected to liability.

Typically, there are three reefer tasks to be done at a container terminal: Connecting reefers, disconnecting reefers and monitoring temperatures.

Disconnecting reefers

Reefers must be disconnected from power so that container handling equipment can move the reefers. When disconnecting the reefer, the current temperature is checked and recorded. If disconnection jobs are completed too late, it can cause a ripple effect on other processes at the terminal. For example, the loading of a vessel can be delayed, or container handling equipment sits idle. On the other hand, if reefers are disconnected too early, it may lead to reefers that are too long without power.

Connecting Reefers

When refrigerated containers arrive at their location in the yard, reefer operatives have to connect the reefer containers to the power grid, check if the target temperature is correct and record the current temperature.

Monitoring Temperature

The temperature of reefers at the terminal must be regularly checked and recorded. It can be done manually, or supported by a solution that records tempereatures, humidity etc. of the reefer unit automatically.

The time a refrigerated container is allowed to be off-power and the frequency the reefer has to be monitored depends on the cargo, the target temperature of the reefer and can differ from terminal to terminal.

With sometimes several hundreds or thousands reefers to be monitored, entire crews will be busy during their entire shift completing this task manually. Remote, electronic reefer monitoring enables high efficiency and cargo safety, providing automated monitoring data for potential claim handling.

Suppliers of cold chain products may need to keep track of specific information about their shipment, depending on the type of products they manufacture. This data includes temperature ranges and other environmental parameters, for example humidity levels, that can compromise the integrity of temperature-sensitive cargo. Armed with this information, shippers can audit their supply chain operations to detect environments and activities that lead to inefficiencies.

Data logging is one technology that makes cold chain supply management easier. It helps secure efficient cold chain monitoring of temperature-sensitive goods. In addition, any quality issues can be addressed before it is too late; therefore, it also supports quality assurance.

Data loggers can be wireless, standalone, web-based, or computer-based. Each option has unique features, pros, and cons that must be carefully reviewed before concluding. Consulting a service provider can help shippers determine the best data logging technology for their cold chain supply needs.

Inspection, customs, documentation

Besides all documents and rules, the shipment owner needs to document the condition of the goods in the reefer container. Otherwise, it is difficult to prove where damages happened and successfully claim them. Container terminals must hand over records of every reefer they were responsible for, either manual or automatic monitoring data.

The cold chain can be local, regional, or global from a geographical viewpoint. The cold chain is local when the point of harvest or production is close to consumption. It’s regional when the point of production and use are in different regions of the same country. Finally, the cold chain turns global when products have to be transported overseas to reach buyers internationally.

In the case of global cold chain, suppliers of temperature-sensitive products may need to clear goods with customs before being allowed to deliver shipment to foreign jurisdictions.

Custom processes can become very influential since temperature-sensitive products tend also to be time-sensitive; in addition, they are subject to more frequent inspection than regular freight. How much time this task takes differs from nation to nation (or economic bloc). A typical issue relates to sanitary inspection that may require fumigation. Interestingly, customs issues are commonly identified as crucial in establishing reliable international cold chains.

A specialised cold chain service provider can handle customs paperwork to decrease shipping delays that may arise from failure to meet all the relevant international shipping requirements. Required documentation includes, among other things, an invoice, export declaration, insurance, packing list, a certificate of origin, bills of lading, and also a shipper’s letter of instruction (SLI). In addition, depending on your shipment, involved parties in the deal and shipment may also require an ATA carnet and a bank draft.

There are some differences in the controlling level of the different parts of the cold chain internationally. Controlling authorities have to pay attention to the handling and distribution related issues of shipped goods and screen containers. A non-intrusive inspection like x-ray and backdoor checks and intensive examinations like contraband exams are possible.

The following organisations are being governed to maintain the standard of products, to define the rules and regulations:

- Regulatory agencies, institutions: The guardian of the cold chain. Some administrations oversee the standard of quality control for shipping food products. Some of the regulatory agencies are listed below for jurisdiction and orders. For the U.S., these are the U.S. customs, the department of transportation, the Transportation Security Administration (TSA), The International Air Transport Association (IATA).

- U.S. Pharmacopoeia (USA): This agency has the authority to make the rules and regulations for the packaging, manufacturing, and distribution of pharmaceuticals related products. Once it is approved, this becomes enforceable in law and nature. In addition, it creates a framework for FDA validation.

- Food and Drug Administration (FDA, USA): This agency is fully responsible for controlling and validating the compliances across the cold chain technology.

- Medical and Healthcare Products Regulatory Agency (MHRA, Europe): In Europe, this institution is responsible for monitoring and enforcement of regulations for medicines.

- The World Health Organization (WHO, Global): For cold chain packaging, this worldwide organization provides global oversight for the packaging, storage, and handling.

Sea transport

On average, the longest part of the journey is on board a vessel. Reefers are tightly stacked and supplied with power to ensure stable temperature and constant airflow.

Chapter 5 goes to the sea and explains the challenges of reefer shipping on oceans.

Container shipments

Maritime transportation has been the dominant mode of global trade since 1,200 BCE. The routes followed coastlines, crossed the oceans, and established maritime networks based on the availability of trade commodities. However, the industrial revolution enabled a dramatic expansion of naval trade networks as steamboats operated outside the usual wind seasons and directions. Trade volume and shipping capacity grew accordingly, and the rise of Information Technology created a dense and timely operating global supply chain.

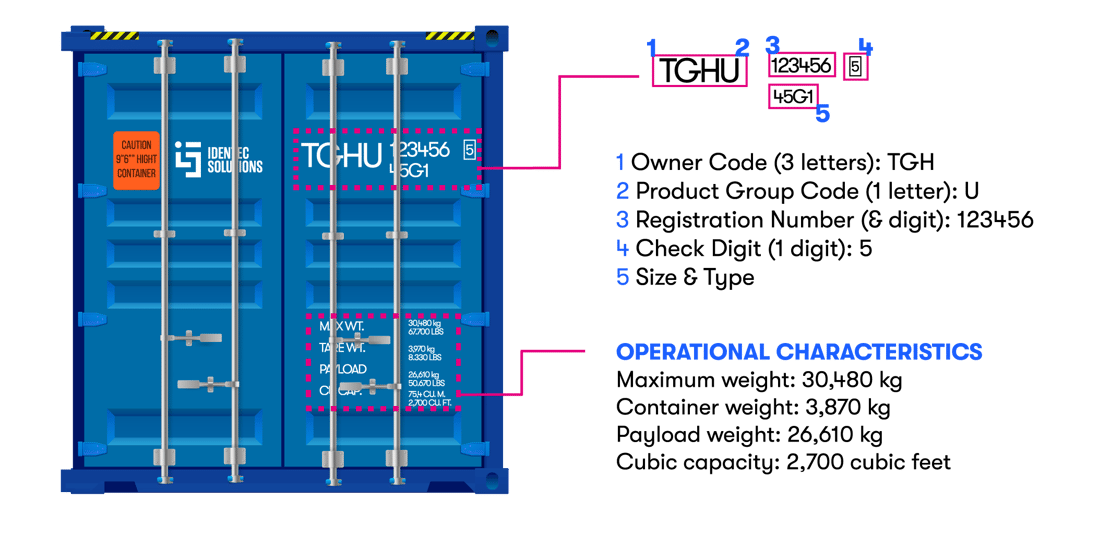

One main obstacle to an efficient supply chain has been transferring goods from one mode of transport to another, mainly because the load unit needed to be changed. Containers revolutionised multi-modal transportation in the 1960ies, setting intermodal standards for containers, container terminals and containerships. It improved cargo loading and unloading time drastically and enabled easy handling of shipments in general. The widely use of containers as load unit within logistics is known as containerisation.

The main advantages of containerisation are:

- Standardisation: Vessels, machines, and infrastructure are adapted to the ISO standard sizes of containers. Therefore, a container can be moved anywhere in the world with all modes of the supply chain. The design of container vessels is optimised to carry a maximum load of containers. Modern container terminals are equipped with cranes and other container handling machinery for the efficient movement of containers.

- Costs of transport: Containers reduced transport costs by a factor of 7 (depending on goods transported) due to the speed and flexibility of handling cargo as containerships increased. System-wide, the effect of bigger vessels has been cost reductions of about 35%.

- Flexible transport unit: Each container has a unique identification number, independent of the goods, ranging from raw materials, manufactured goods, and even liquids in specialised containers. This way, containers are easy to distribute. They offer security to the transported goods (to a certain extent), reducing damages, spoilage or losses.

But containerisation also creates challenges:

- Significant investments: Containers and container handling demand big capital investments.

- Empties: Empty containers are needed to be loaded with goods. Once unloaded, they have to be made available again. Empty containers may accumulate in some parts of the global supply network, clogging needed space in terminals. It is not uncommon that entire ships transport empty containers back to locations where containers are missing.

- Trafficking of illegal cargo: Containers are used to transport illicit goods because they make a quick inspection impossible. Customs manually inspect only 1-5% of all containers handled at ports.

- Need for space in terminals: Because ships are getting bigger, available space for unloading containers must grow accordingly. 5,000 TEU requires a minimum of 12 hectares of stacking space.

Container Identification

Reefer shipments

Refrigerated cargo was shipped as early as the 1870’s, carrying frozen mutton from Argentina to France and from Australia/NZ to the UK. Until the innovation of containers, reefer ships were typically refrigerated cargo ships with isolated chambers. Bananas, fruit, and meat have historically been the main cargo of refrigerated ships. Roughly 900 registered merchant ships are designated as refrigerated cargo ships today.

The methods by which a modern reefer vessel works, were established more than 100 years ago, although come with continual refinement and improved efficiencies. A reefer ship can barely be identified from the outside and looks almost like a classic freighter. Before the 1970’s, vessels transported perishables in so-called cooling zones: decks of 2.20 meters height, especially insulated against high tropical outside temperatures.

Compression refrigeration systems kept the temperatures for the duration of the voyage. Inside there are numerous measuring points, thanks to which temperatures are continuously monitored. In addition, due to its purpose, a reefer vessel is often more heavily motorised and reaches higher speeds.

Since the 1970s, refrigerated containers have been in use, in which the refrigeration technology inside the container is fully automatic. The design of reefer vessels changed accordingly. Containerised loads are transported on special refrigerated container ships or “normal” container ships with additional electrical distribution equipment. They can be grouped into refrigerated container ships, so-called side-door vessels or retrofitted conventional ships or vessels.

With an integral container, all the functions of a reefer vessel can be performed. All that is required is a power supply, the rest is fully automatic, and compliance with the cold chain is observed and the data transmitted.

Specially insulated containers have been produced exclusively in China since 2007. Their share was 60 per cent in 2008. Almost all container ships in service can transport refrigerated or integral containers and provide the appropriate connections. Since 2010, slots for such containers have been around 18 per cent.

Under sea-going conditions, the number and rating of service generators shall be sufficient to supply all sockets and the hold ventilation in addition to the ship essential services when any generator set is out of service. Ships designed for the carriage of more than 150 reefer containers are to be equipped with a remote reefer container monitoring system of the power cable transmission type. Some refrigerated containers already work with RFID transponders, thanks to which the position, temperature, and humidity can be monitored and read around the clock.

Reefer container standards

The ISO 1496-2 describes the basic specifications and testing requirements for ISO series 1 thermal containers for international exchange and for conveyance of goods by road, rail and sea, including interchange between these forms of transport.

The following documents are referred to the ISO 1496-2 document as requirements:

- ISO 668, Series 1 freight containers — Classification, dimensions and ratings

- ISO 1496-1, Series 1 freight containers — Specification and testing

- ISO 1161, Series 1 freight containers — Corner fittings — Specification

- ISO 6346, Freight containers — Coding, identification and marking

- ISO Guide 51, Safety aspects — Guidelines for their inclusion in standards

- IEC 60309-2, Plugs, socket-outlets and couplers for industrial purposes — Part 2: Dimensional interchangeability requirements for pin and contact-tube accessories

The Last Mile

The last leg or mile of the cold chain reaches the end-consumer - either as input in a production process or in a grocery store to be consumed. Despite individual delivery, the cold chain must remain unbroken.

Chapter 6 discusses the challenge of an undisrupted chain on the last mile to the customer.

The uninterrupted cold chain

Large scale cold chain distribution center

A cold chain distribution center is usually designed as a crossdocking facility: inbound and outbound shipments are serviced on opposites sides. Not surprisingly, power consumption is the most important operating cost for a refrigerated warehouse.

Within the warehouse are several compartments of different temperatures to support specific cold chain requirements according to different temperature ranges.

A successful cold chain ensures temperature-sensitive products are kept within required temperature ranges from the warehouse, farm or factory to the end user. Think of ice cream: It must be kept frozen to preserve its shelf life and consistency. If temperatures rise above the sub-zero ranges, the product will lose its solid state and will be considered unsaleable.

Suppliers of food and pharmaceutical goods heavily rely on the cold chain to ensure shipment is not compromised before their products reach the market. While streamlining the cold chain process and delivery of their goods is a priority, suppliers experience may lie more in production and manufacturing. On the other side, shipping companies ensure timely and efficient delivery of their temperature-sensitive goods to consumers.

The result of failing to maintain specified temperatures at each step of the cold chain, even for short periods, may result in undesirable outcomes. These may include the following:

Product degradation

When a cold chain shipment isn’t kept within specification at every link of the chain, the quality of the shipment will probably be compromised, resulting in useless products. This may be critical in the case of shipping vaccines, pharma products, and essential food items.

Waste of suppliers’ money

When cold chain cargo goes bad because of failure to provide the consistent temperatures required, suppliers lose money. The extent of financial losses may depend on a range of factors including the type and quantity of products involved.

High-value refrigerated products will lead to greater losses than cheaper products of the same truckload. The value of a reefer full of banana may be around 50.000 USD. Pharmaceuticals can cost several million USD per reefer.

Deterioration of business partnerships

When suppliers suffer heavy losses due to mistakes committed by their shipping partners, they will take legal action which takes time and requires financial resources to resolve. In addition, severing ties with their partners also affects future earnings and reputaion.

End-user consumer discontent

When cold chain products don’t reach the consumer market due to quality issues, consumers can become motivated seeking alternatives, which impacts brand loyalty.

The last mile

Trade and consumers benefit from the technologies and processes of the cold chain. On a global scale, regions can specialize in agricultural products, unaffected by the distance to a potential market. The benefits from a regional point of view are better supply in quantities and range of products using regional cold storage facilities. The local grocery store profits as well, as it enables timely distribution of perishables to end-consumers and restaurants.

The last stage of the cold chain or the “last mile” is the actual delivery of the shipment to its destination. There are several aspects to consider:

- The destination and the timing of the delivery: Workers and warehousing space must be available.

- Modes of transportation: Trucks and vans must meet the specifications necessary to transfer the cold chain shipment. Imagine narrow sideroads to a grocery shop or limited parking availability.

- Movement into the new cold storage facility: Potential for a breach of integrity if transfer takes too long.

Quality assurance plays an integral role in this process. End-consumer must be sure there have been no anomalies during the transportation and the products are safe. Otherwise, affected products must be labelled as such and removed if necessary.

Quality assurance is the step of the logistical process that creates confidence and accountability, mainly if liability for a damaged shipment is incurred. If problems compromise a load, efforts must be made to identify the source and eliminate the cause.

One aspect of quality assurance is the growing consumer trend to ask for the origin and the journey of the product. Authenticating fresh food needs data that is collected automatically along the cold chain. Evolving technologies and regulations will create an even more transparent route for fresh foods, and leading retailers will find smart ways to transform this data into marketing messaging to foster loyal customers.

Besides showing a historical record of the specific cold chain journey of a product, new technologies allow retailers to manipulate goods related to the forecasted demand (see below): Smart reefer containers could use ozone generating units, venting valves and other measures create optimal conditions and control the ripening process – from a remote location!

Instantly knowing a container’s current state can avoid problems. For instance, as the temperature rises, an alert is triggered in the system. The reefer owner can then settle the matter with a call to the loading dock rather than issuing a claim.

Additionally, the reefer may use automated means to maintain the temperature and climate to strict parameters, regularly sending its location and status to the cloud. For managers tasked with handling supply and minimizing loss, it’s just one way that greater visibility into the cold chain is driving new efficiencies.

Before Covid-19, the last mile delivery ended typically in grocery stores or restaurants. But the global pandemic accelerated a new trend of grocery home-delivery. Groceries, restaurants, and meal-delivery services are offering home-delivery to a steady growing customer base. Healthy eating trends increase the complexity of food delivery as these organic products have a shorter shelf-life and must be sold in a short time.

On the other hand, consumers’ environmental concerns are only growing, and they expect their grocers to develop sustainable practices too: Lowering their carbon emissions and reducing waste. Therefore, timely and optimal processes are needed to ensure high quality, product availability and avoiding waste and emissions. The last-mile of the cold chain is a challenging road and will rely more and more on AI to plan future demand “just-in-time”.

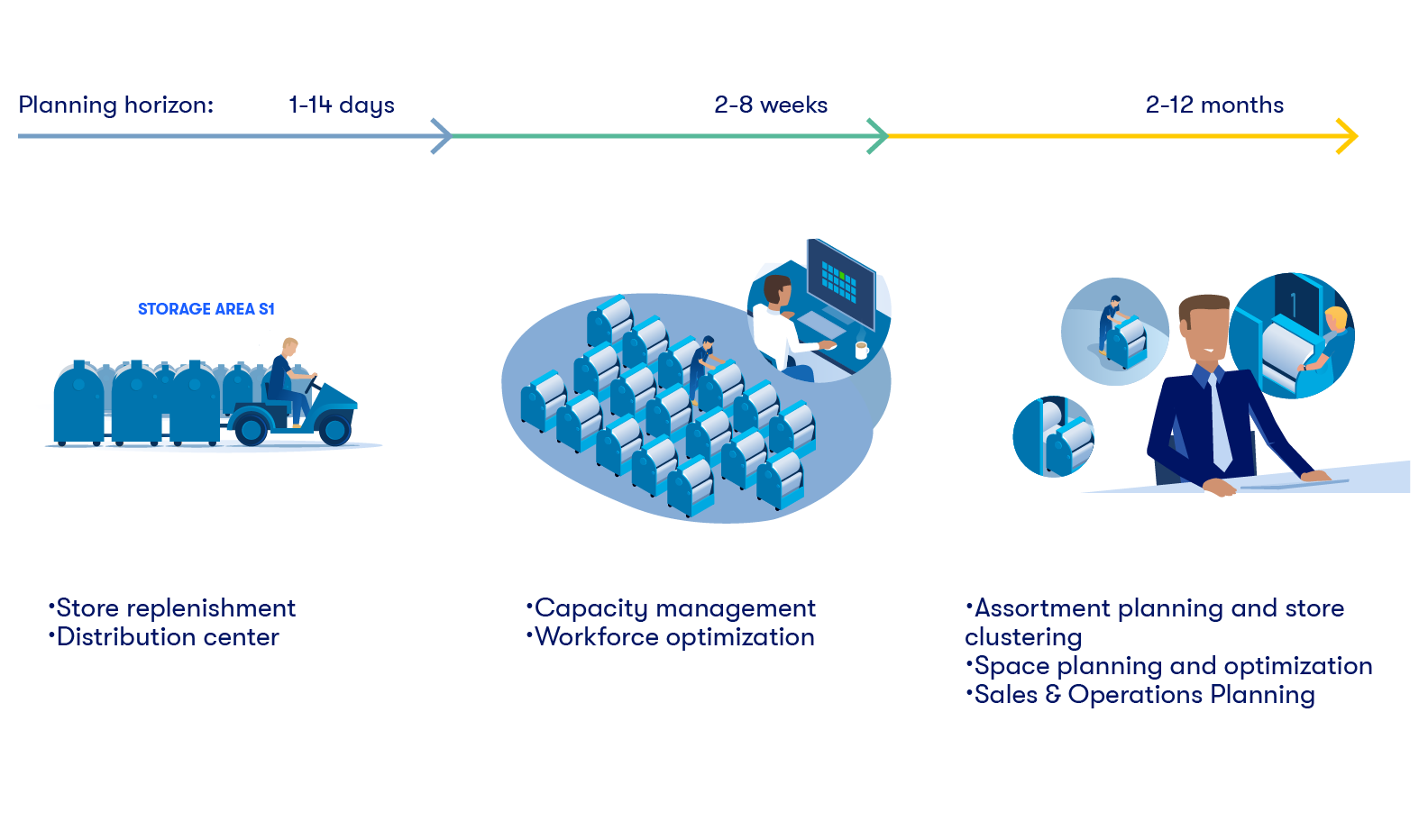

Planning horizon of a distribution center

eBook Format

Download this web page in a comfortable pdf-format: a 50+ pages, free eBook including chapter summaries, key takeaways and more illustrations.

Share it with your colleagues and improve your cold chain know-how and processes.

Delve deeper into one of our core topics: Refrigerated containers